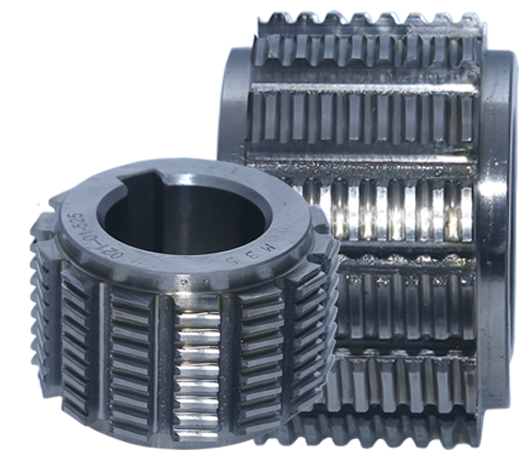

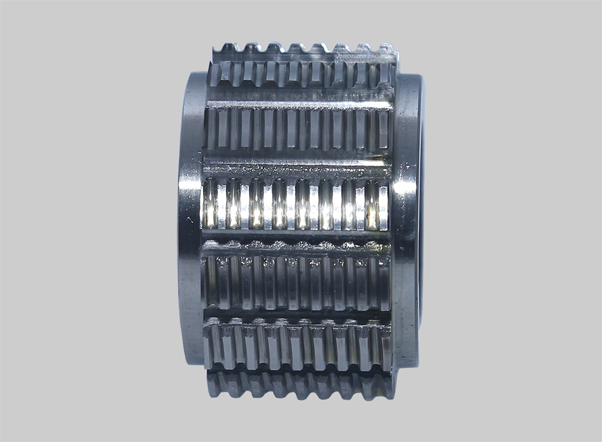

Timing Pulley Hobs

Manufactured using high-quality raw materials and advanced manufacturing processes, our hobs offer excellent durability, dimensional stability, and long tool life. We also provide custom timing pulley hobs as per customer drawings, specifications, and application requirements, making them ideal for both standard and specialized industrial applications.

We also support OEM and export requirements, delivering reliable gear-cutting solutions with assured quality and on-time delivery.

Technical Specification

| TIMING PULLEY HOBS | |

|---|---|

| Materials | M2/S590/ASP2052/ S390/S290/ ASP 2030 / M35 |

| Involute Spline Standards | BS4548, DIN7721, ISO5294, ISO5296, ISO17396 |

| Accuracy | AAA, AA and A as per DIN 3968 |

| PVD Coatings | Supplied with all types of PVD Coatings. |

| Involute profiles like ‘T’ & ‘S’ | |

| Linear pulleys like MXL, XL, L, H, XH, XXH | |

Product FAQ’s

Q. Can timing pulley hobs handle high production loads?

Yes, HSS timing pulley hobs are designed for continuous industrial production. They can handle high cutting loads with proper parameters. Stable performance is achieved with correct speeds and feeds. Tool life remains consistent under controlled conditions.

Q. What coatings are available for HSS timing pulley hobs?

Optional coatings include TiN, TiAlN, and other PVD coatings. Coatings improve wear resistance and tool life. They reduce friction during cutting. Coated hobs are preferred for higher production runs.

Q. Which industries use timing pulley hobs?

Timing pulley hobs are used in automotive and industrial machinery sectors. They are common in automation, robotics, and conveyor systems. Electric motor and gearbox manufacturers rely on them. They are essential for precision motion control components.

Q. How is tooth profile accuracy ensured in production?

Super Tools maintains tooth profile accuracy through CNC profile grinding. Digital controls ensure precise pitch and geometry. In-process inspections detect deviations early. This guarantees reliable pulley tooth generation.

Q. How is raw material quality verified before production?

Super Tools inspects raw HSS material for chemical composition. Hardness testing is conducted before machining. Only certified HSS grades are approved. This ensures reliable tool performance.

Q. How does manufacturing quality impact hob performance?

Super Tools’ precision manufacturing ensures accurate pulley tooth generation. Improved surface finish reduces vibration and noise. Consistent geometry increases belt life. Overall transmission efficiency is enhanced.

Q. Are metric and inch timing pulley hobs both available?

Yes, HSS timing pulley hobs are available in both metric and inch standards. This supports global machine tool compatibility. Manufacturers can match pulley specifications easily. This flexibility is important for export-oriented production.

Q. What surface finish can be achieved using HSS timing pulley hobs?

Fine surface finishes are achievable with optimized parameters. Accurate geometry reduces tool marks. Coatings further improve finish quality. Smooth finish enhances belt performance.

Q. Can HSS timing pulley hobs be re-sharpened?

Yes, they can be re-sharpened multiple times. Regrinding restores cutting edges while maintaining profile accuracy. This extends tool life significantly. Proper regrinding guidelines should be followed.

Our Range of HSS Hob Cutters

Gear Hobs

STC is a Manufacturer of Gear Hobs made with maximum accuracy and proper finishing.

Spline Hobs

We are a Manufacturer of Spline Hobs, in Standard and specific customer requirements.

Accuracy class:

Sprocket Hobs

We can also manufacture Chain Sprocket Hobs as per customer requirements or drawings.

Accuracy Class:

Timing Pulley Hobs

We are a Manufacturer of Timing Pulley Hobs in high quality as per ANSI, BS, IS, or any other...

Accuracy :

Worm Hobs

Serration Hobs

We are a Manufacturer and Exporter of Serration Hobs, which are used for generating gears of maximum...

Special Profile Hobs

Besides Standard Gear Hobs, we also Manufacture Special Profile for various components like missing...