Solid Carbide Milling Cutters

STC is a Manufacturer and Exporter of Solid Carbide Milling Cutters, generally used in CNC machining centers and CNC engraving machines. Carbide Milling Cutters are made from high-grade Solid Carbide material to ensure superior strength, wear resistance, and dimensional stability. These milling cutters can also be loaded into conventional machines to process hard and uncomplicated heat-treated materials with consistent performance.

STC Solid Carbide Milling Cutters deliver excellent cutting accuracy, longer tool life, and high thermal resistance under demanding machining conditions. They are suitable for machining steel, stainless steel, cast iron, and other difficult-to-cut materials. Precision flute geometry ensures smooth chip evacuation and improved surface finish.

Besides standard Solid Carbide Milling Cutters, we also provide customized milling cutters as per specific customer requirements, drawings, or applications.

Carbide Milling Cutters are mainly divided into following types

- Solid Carbide Milling Cutters

- Carbide Straight Shank Milling Cutters

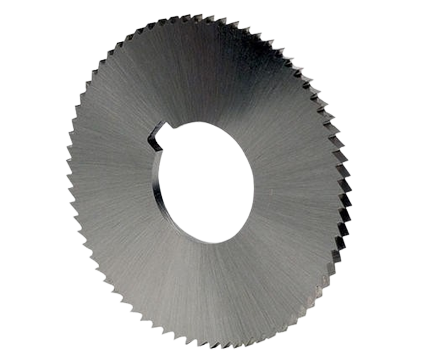

- Carbide Saw Blades Milling Cutter

- Carbide Auger milling Cutters

Carbide Milling Cutters are mainly divided into following types

Solid Carbide Milling Cutters

Carbide Straight Shank Milling Cutters

Carbide Saw Blades Milling Cutter

Carbide Auger milling Cutters

Product FAQ’s

Q. What are Solid Carbide Milling Cutters?

Solid carbide milling cutters are precision cutting tools made entirely from tungsten carbide. They are designed for high-speed and high-accuracy machining. These cutters offer excellent rigidity and wear resistance. They are widely used in modern CNC milling operations.

Q. Are solid carbide milling cutters suitable for CNC machines?

Yes, solid carbide milling cutters are specifically designed for CNC machining applications. Their rigidity ensures stable cutting, reduced vibration, and high dimensional accuracy. They perform exceptionally well in high-speed and automated production setups.

Q. Do solid carbide milling cutters reduce machining time?

Yes, their ability to operate at higher speeds and feeds reduces overall cycle time. Faster material removal and fewer tool changes improve productivity. This is especially beneficial in high-volume production.

Q. Can solid carbide milling cutters be customized for OEM use?

Yes, Super Tools Corporation offers OEM customization for solid carbide milling cutters, including geometry, coating, flute count, and overall dimensions. Customized cutters are engineered to improve machining efficiency, accuracy, and tool life for specific production needs. Such OEM solutions are widely used in automotive, aerospace, and specialized manufacturing applications.

Q. What coatings are used on solid carbide milling cutters?

Common coatings include ALCRONA Pro & ALTENSA. These coatings reduce friction, increase wear resistance, and improve heat tolerance. Coated cutters perform better in high-speed and dry machining conditions.

Q. How long do solid carbide milling cutters last?

Tool life depends on material being machined, cutting parameters, coating, and machine rigidity. Under optimized conditions, solid carbide cutters last significantly longer than conventional tools. Proper usage and timely Sharpening further extend their life.

Q. Are solid carbide milling cutters suitable for high-speed machining (HSM)?

Yes, solid carbide milling cutters are ideal for high-speed machining applications. Their rigidity supports stable cutting at high RPMs. This results in superior surface finish and productivity.

Q. Can solid carbide milling cutters be used for roughing and finishing?

Both roughing and finishing cutters are available in solid carbide. Roughing cutters handle heavy material removal efficiently. Finishing cutters deliver smooth surfaces and tight tolerances.

Q. How do solid carbide milling cutters improve surface finish?

Sharp cutting edges and rigid structure reduce tool marks. Advanced coatings minimize friction. This results in consistent and smooth surface finishes.

Q. Are solid carbide milling cutters suitable for long production runs?

Solid carbide milling cutters are designed for durability and consistency. They maintain cutting performance over extended cycles. This makes them ideal for mass production environments.

Our Range of Milling Cutters

Form Milling Cutter

STC is a Manufacturer of Form Milling Cutters. We have a experts team in designing & manufacturing...

Rack Milling Cutter

We are a Manufacturer of Rack Milling Cutters, made in Single or multiple rows with Straight...

Involute Gear Cutter

We are a Manufacturer of Involute Gear Cutters. The bright finish coating on the cutting edges...

HSS Slitting Saw Cutter

We provide an extensive range of Slitting Cutters, which are ideal for metalworking applications...

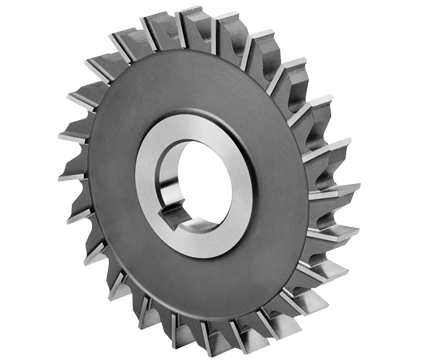

Side and Face Milling Cutter

We are a Manufacturer of Side and Face Cutter, which made in various diameters depending on usage...

Solid Carbide Milling Cutter

STC is a Manufacturer and Exporter of Solid Carbide Milling Cutters, generally used in CNC machining...