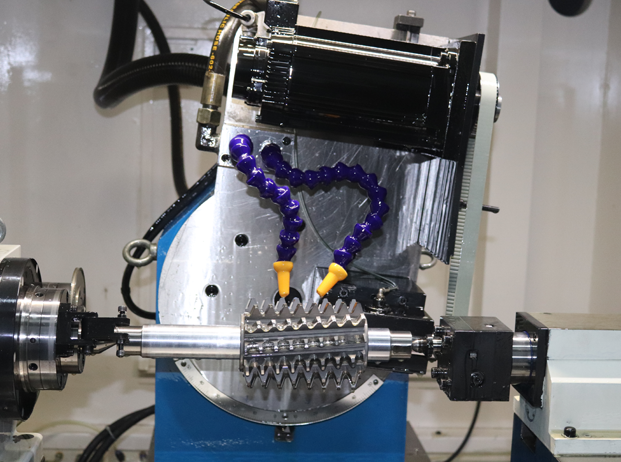

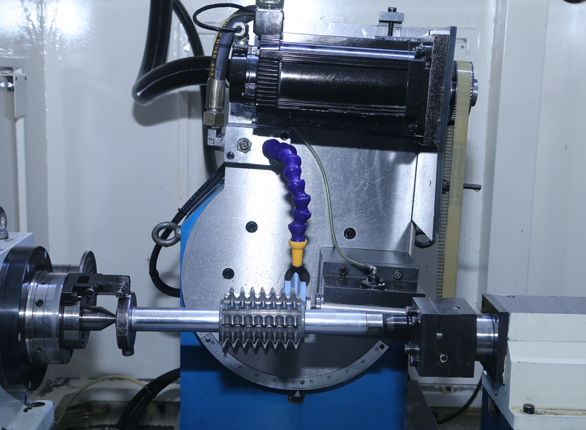

CNC Hob Profile Grinding Machine

At Super Tools, we use CNC Hob Profile Grinding Machine to deliver unmatched precision and reliability for our customer’s. CNC Hob Profile Grinding Machines are engineered for ultra-high accuracy grinding of gear hobs, spline hobs, worm hobs, and special form hobs used in precision gear manufacturing. These automatic hob profile grinding machine ensure exact tooth profile geometry, uniform cutting-edge accuracy, and excellent surface finish across the entire hob length. Through CNC hob profile grinding with high accuracy, the machine consistently maintains tight tolerances required for high-performance gear cutting applications.

Technical Specification

| CNC Hob Profile Grinding Machine |

|---|

| Very short grinding cycle |

| Increased Production |

| Grinding accuracy “AAA” according to DIN 3968 |

Benefits of CNC Hob Profile Grinding Machine

Supports full CNC automation, reducing human error and enhancing repeatability.

Enables regrinding and profile correction, restoring worn hobs to original specifications.

Provides flexibility for different hob modules, pressure angles, and profiles.

Reduces overall production time and operational costs through efficient grinding cycles.

Allows easy programming and quick changeovers for small batches or mass production.

Enhances tool life consistency, minimizing scrap and rework.

Key Functional Uses of Hobs: –

- Gear hob manufacturing, profile grinding.

- Gear Hobs for Automotive transmission gears, differential gears, and drivetrain components.

- Used for Industrial gearbox manufacturing for heavy-duty and continuous-duty applications.

- Best For Aerospace gear systems requiring high accuracy and strict profile tolerance.

- Suitable for Defence equipment gear components with critical performance requirements.

- Applied in Machine tool industry for cutting tool production and refurbishment.

- Ideal for Wind energy and renewable power transmission gear applications.

- Engineered for Construction equipment gears for excavators, loaders, and cranes.

- Preferred for Railway traction and rolling stock gear manufacturing.

- Capable of Heavy engineering industries producing large and complex gear systems.

- Trusted by Precision tool rooms and gear research & development facilities.

- Recommended for OEM gear manufacturers and export-oriented production units.