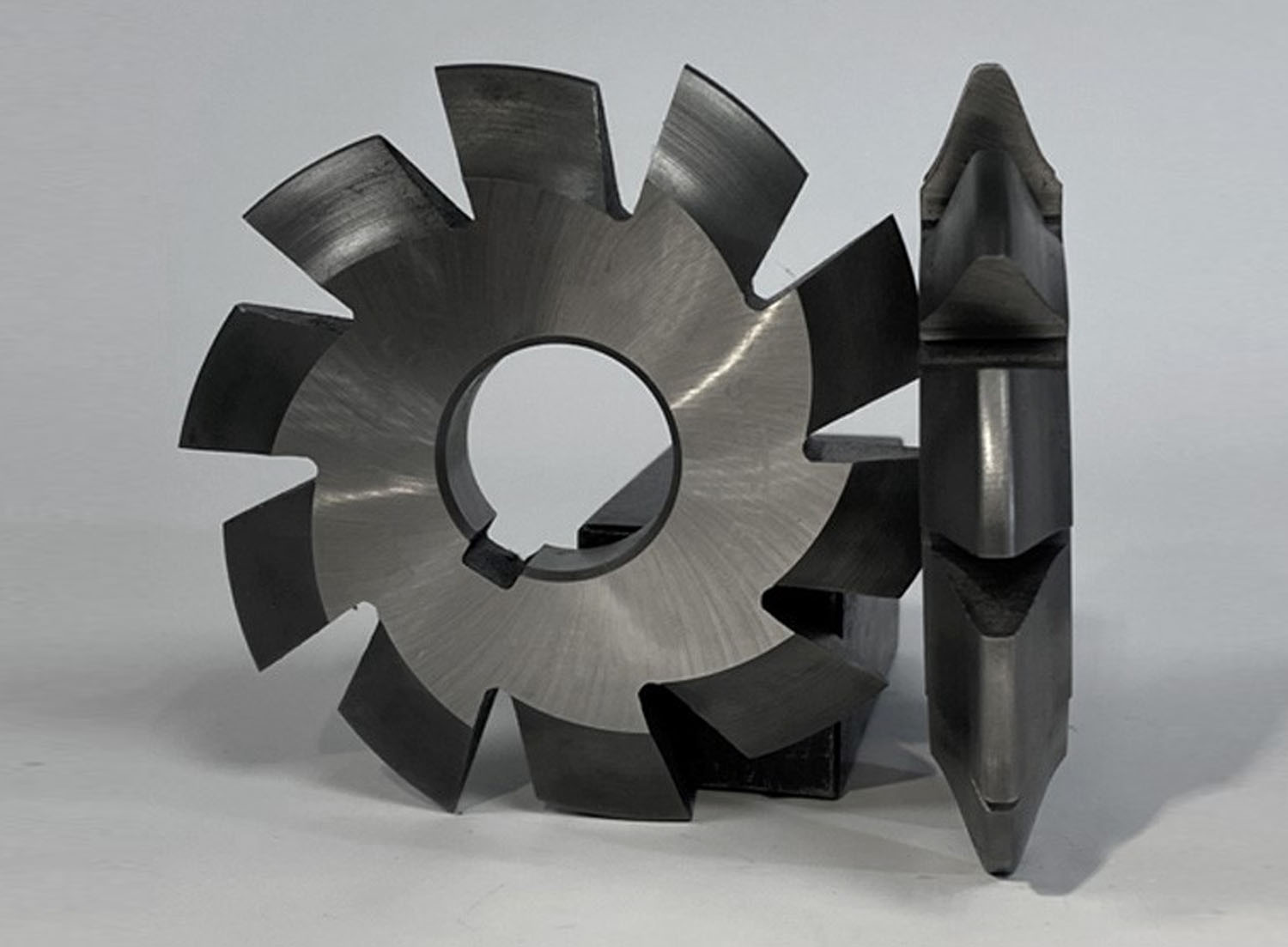

Involute Gear Cutter

We are a Manufacturer of Involute Gear Cutters, engineered for precision and durability in demanding machining environments. These milling cutters are specially designed to withstand extreme hardness and heavy working conditions where operating temperatures exceed 600 degrees. The bright finish coating on the cutting edges enhances wear resistance, ensuring sturdy performance and long service life. All our milling cutters are manufactured using advanced technology that combines premium steel grades and high-quality alloys for superior blade strength. Our Involute Gear Cutters deliver consistent accuracy, smooth cutting action, and reliable results across high-load applications. They are ideal for gear manufacturing and precision machining industries seeking long-term productivity and reduced tool replacement costs. If you have questions, contact us today or request a quote for customized solutions.

Technical Specification

| INVOLUTE GEAR CUTTERS | |

|---|---|

| Material | HSS M2, M35, M42, and ASP 2030 |

| Module Range | 0.5 to 32 Module |

| Coating | Supplied with all types of coatings. |

| Standard | BS, IS, DIN or as required |

| Accuracy class | Up to AA |

Product FAQ’s

Q. What is an involute gear cutter?

An involute gear cutter is a precision cutting tool used to machine involute gear tooth profiles accurately. It is designed to generate correct pressure angles and smooth flank geometry. These cutters are commonly used in gear manufacturing and transmission components. They ensure consistent tooth accuracy and reliable gear performance.

Q. What technical specifications define an involute gear cutter?

Key specifications include module or DP, pressure angle, number of teeth, cutter diameter, and face width. Material grade and heat treatment determine strength and wear resistance. Coatings such as TiN or TiAlN improve tool life. Precision grinding ensures accurate involute geometry.

Q. Where are involute gear cutters commonly used?

They are widely used in automotive gears, industrial gearboxes, pumps, and power transmission systems. Applications include spur gears, external splines, and precision gear components. Tool rooms and batch production facilities rely on them. They are ideal for accurate and repeatable gear tooth machining.

Q. Can involute gear cutters be customized as per drawing?

Yes, involute gear cutters can be manufactured as per customer drawings and gear data. Custom modules, pressure angles, and tooth forms are achievable. Special coatings and cutter dimensions can be provided. Customization ensures perfect compatibility with specific gear designs.

Q. How should an involute gear cutter be installed and maintained?

The cutter should be mounted on a clean, rigid arbor with correct clamping torque. Proper alignment prevents runout and uneven wear. Regular inspection and re-sharpening extend tool life. Using recommended cutting parameters avoids premature failure.

Q. Are involute gear cutters suitable for CNC machines?

Yes, involute gear cutters are fully suitable for CNC milling and gear cutting machines. They perform well under controlled feed rates and spindle speeds. CNC compatibility ensures repeatable accuracy and surface finish. Proper programming maximizes cutter efficiency.

Q. Can involute gear cutters be re-sharpened?

Yes, involute gear cutters can be re-sharpened multiple times depending on design. Re-sharpening restores cutting edges without altering involute accuracy. Professional grinding maintains profile integrity. This reduces tooling cost and increases overall productivity.

Q. Are involute gear cutters suitable for hardened materials?

Yes, carbide, PM and HSS steel involute gear cutters are suitable for hardened materials. Proper coatings enhance wear resistance at higher hardness levels. Controlled cutting conditions are essential. This enables efficient machining of heat-treated components.

Q. Why choose involute gear cutters for small batch production?

They offer flexibility and lower tooling investment compared to hobs. Ideal for prototypes, repairs, and small production runs. Quick setup saves machining time. They provide precise results without high tooling costs.

Q. Are involute gear cutters compatible with manual milling machines?

Yes, involute gear cutters can be used on both manual and CNC milling machines. Proper setup and indexing are required for accuracy. Manual machines are suitable for small batches. This offers flexibility across different workshops.

Our Range of Milling Cutters

Form Milling Cutter

STC is a Manufacturer of Form Milling Cutters. We have a experts team in designing & manufacturing...

Rack Milling Cutter

We are a Manufacturer of Rack Milling Cutters, made in Single or multiple rows with Straight...

Involute Gear Cutter

We are a Manufacturer of Involute Gear Cutters. The bright finish coating on the cutting edges...

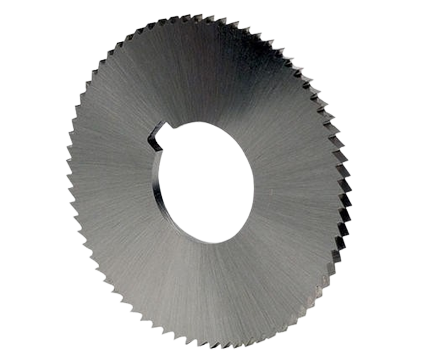

HSS Slitting Saw Cutter

We provide an extensive range of Slitting Cutters, which are ideal for metalworking applications...

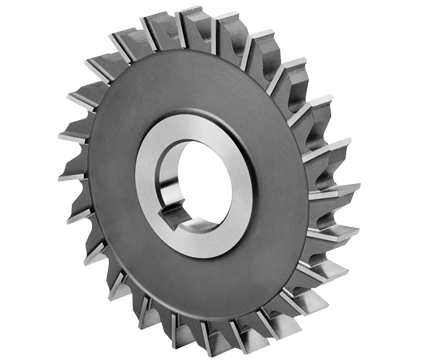

Side and Face Milling Cutter

We are a Manufacturer of Side and Face Cutter, which made in various diameters depending on usage...

Solid Carbide Milling Cutter

STC is a Manufacturer and Exporter of Solid Carbide Milling Cutters, generally used in CNC machining...