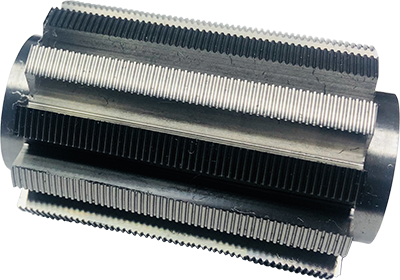

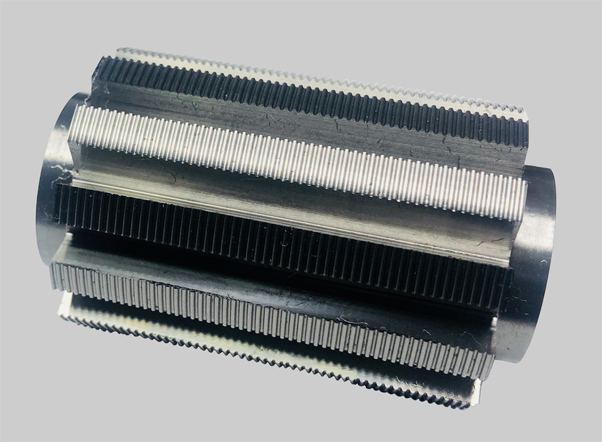

Serration Hobs

In addition, STC Serration Hob Cutters offer excellent surface finish and stable cutting performance during continuous operations. These cutters are suitable for machining a wide range of ferrous and non-ferrous materials. We also manufacture custom serration hobs as per customer drawings, specifications, and application needs. Each hob undergoes strict quality inspection to ensure dimensional accuracy and reliable performance in demanding production environments.

Technical Specification

| SERRATION HOBS | |

|---|---|

| Materials | S390/ ASP2052/ ASP2030/ S290/ ASP2060/ M35/ M2/ S590 |

| Standard | DIN 5480, DIN 5482, ANSI B92.1, B92.2, BS3550, GOST-6033 |

| Accuracy Class | AAA/AA/A as per DIN 3968 |

| PVD Coating | Supplied with all types of latest PVD Coatings. |

Product FAQ’s

Q. What types of serration profiles can be produced using serration hobs?

Serration hobs can produce straight, involute, angled, and special serration profiles. The profile depends on application requirements and mating component design. Custom profiles are also possible for OEM needs. This flexibility makes them suitable for diverse industries.

Q. Which industries commonly use HSS Serration Hobs?

These hobs are widely used in automotive, aerospace, power transmission, heavy machinery, and industrial equipment manufacturing. They are ideal for producing precision shafts, couplings, and hubs. Consistent quality makes them suitable for mass production. OEM manufacturers rely on them for accuracy.

Q. What materials can be cut using HSS Serration Hobs?

HSS Serration Hobs can machine carbon steel, alloy steel, stainless steel, and non-ferrous metals. Proper cutting parameters ensure optimal performance. Coated hobs can handle tougher materials. Material selection impacts tool life and finish quality.

Q. Which Indian supplier offers export-quality HSS serration hobs?

Super Tools is recognized as a top serration hob cutter manufacturer in India, supplying export-quality HSS serration hobs that meet international standards. Strict inspection and controlled heat treatment ensure consistent quality.

Q. What are the standard technical specifications of serration hobs?

Specifications include module or pitch, pressure angle, number of starts, outside diameter, and bore size. These parameters define the final serration geometry. Precision grinding ensures dimensional accuracy. Customization is also available.

Q. Do serration hobs support both metric and inch standards?

- Yes, Super Tools provides serration hobs in both metric and inch standards.

- The hobs are manufactured with precise tooth geometry to meet global specifications.

- This allows seamless use across international machines and OEM applications.

Q. Which Indian manufacturer supplies precision HSS serration hob cutters?

Super Tools is known as a top serration hob cutter manufacturer in India, delivering precision-ground HSS serration hobs for demanding industrial applications. Advanced CNC manufacturing ensures consistent tooth profiles and high dimensional accuracy.

Q. Are HSS Serration Hobs suitable for high-volume production?

Yes, they are widely used in medium to high-volume production lines. HSS material provides durability under continuous operation. Proper coating further increases output capacity. Consistent results reduce downtime.

Q. What role does heat treatment play in HSS Serration Hobs?

- Heat treatment improves the hardness and toughness balance of HSS Serration Hobs.

- It enhances wear resistance and prevents premature edge chipping during cutting.

- Proper heat treatment ensures consistent performance and longer tool life.

Our Range of HSS Hob Cutters

Gear Hobs

STC is a Manufacturer of Gear Hobs made with maximum accuracy and proper finishing.

Spline Hobs

We are a Manufacturer of Spline Hobs, in Standard and specific customer requirements.

Accuracy class:

Sprocket Hobs

We can also manufacture Chain Sprocket Hobs as per customer requirements or drawings.

Accuracy Class:

Timing Pulley Hobs

We are a Manufacturer of Timing Pulley Hobs in high quality as per ANSI, BS, IS, or any other...

Accuracy :

Worm Hobs

Serration Hobs

We are a Manufacturer and Exporter of Serration Hobs, which are used for generating gears of maximum...

Special Profile Hobs

Besides Standard Gear Hobs, we also Manufacture Special Profile for various components like missing...