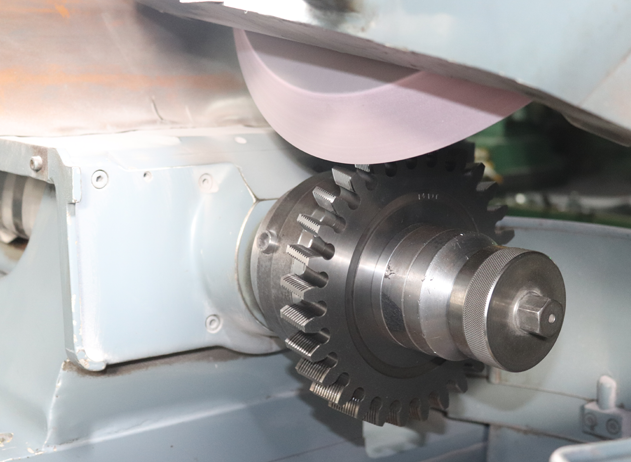

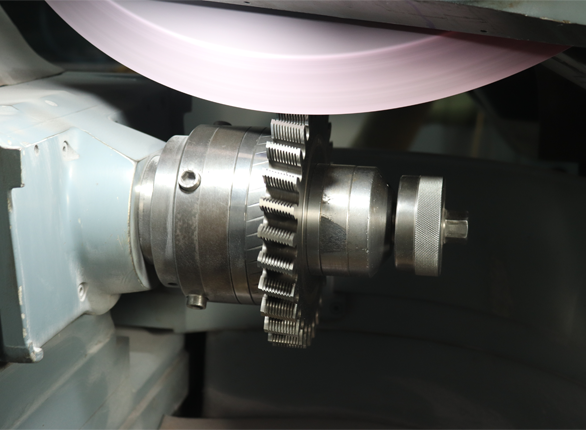

Hurth Shaving Cutter Grinding Machine

Core Applications: –

Automotive Industry

Grinding of precision shaving cutters used in gear manufacturing for transmissions, differentials, and engine components.

Aerospace Industry

Production of high-precision shaving cutters for turbine gears, aircraft transmissions, and precision aerospace assemblies.

Industrial Gear Manufacturing

Grinding of Hurth shaving cutters used in industrial gear production for machinery, robotics, and heavy equipment.

Machine Tool Industry

Grinding and testing of cutting tools and precision shaving cutters used in tool room applications.

Energy & Power Generation

Cutter grinding for industrial gears used in turbines, generators, and wind power gearboxes.

Railway & Transportation

Production and validation of shaving cutters for railway gear assemblies, bogies, and traction systems.

Defense & Military Applications

Precision grinding of cutters for military vehicle transmissions and defense machinery gears.

Warehouse Facility Advantage

- Centralized facility with organized layout enables smooth material movement and efficient coordination between machining, grinding, and inspection processes.

- Safe and controlled handling of machines, tools, and components helps maintain precision, accuracy, and long-term equipment reliability.

- Adequate space for machine setup, trial runs, and process validation supports accurate execution before final delivery.

- Streamlined internal logistics reduce processing time and support faster response to customer requirements.

- Dedicated zones for inspection and technical evaluation ensure consistent quality control at every stage.

- Well-managed infrastructure improves overall operational efficiency, resulting in reliable, on-time support for customer applications.

- Structured storage and workflow planning reduce the risk of handling errors, rework, and production delays.

- Scalable facility capacity supports future expansion, higher production volumes, and evolving customer requirements.