Q. What is broach re-sharpening?

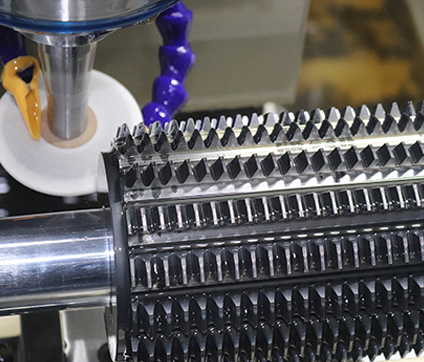

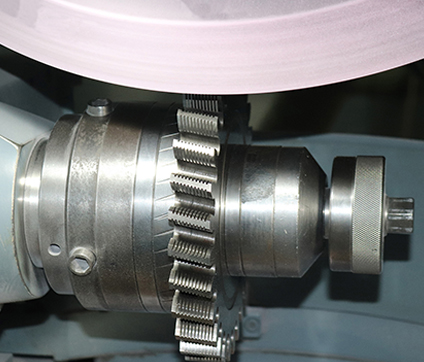

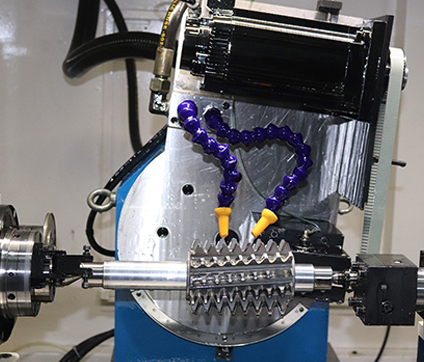

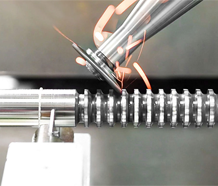

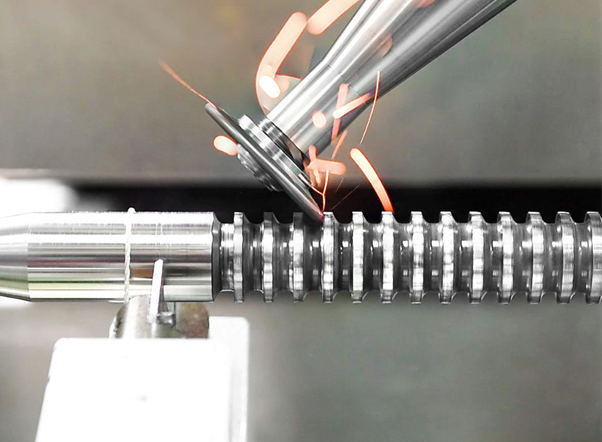

Broach re-sharpening is the process of restoring worn cutting edges while maintaining the original tooth geometry of the broach. It ensures consistent and precise broaching performance. The process improves surface finish, reduces cutting forces, and extends overall tool life. Precision grinding guarantees dimensional accuracy across repeated production cycles.

Q. What types of broaches can be re-sharpened?

Super Tools can re-sharpen a wide variety of broaches, including keyway, spline, surface, and custom-profile broaches. Both standard and specialized tools are restored with precision. Each broach is handled carefully to meet original specifications, ensuring reliable performance in all applications.

Q. Will re-sharpened broaches perform like new?

Yes, Super Tools precision grinding restores tooth geometry and dimensional accuracy. Re-sharpened broaches deliver smooth surface finishes, optimal cutting forces, and consistent performance across repeated production cycles. Quality checks by Super Tools ensure every tool meets rigorous standards.

Q. Do you perform quality checks after re-sharpening?

Yes, every broach undergoes detailed inspection to verify dimensional accuracy and tooth geometry. Cutting performance, surface finish, and stability are also checked. Only broaches that meet strict quality standards are returned to clients. This ensures reliable performance in your production process.

Q. How many times can a broach be re-sharpened?

Most broaches can be re-sharpened multiple times until the geometry is no longer safe to restore. The exact number depends on the broach material, design, and wear level. Each re-sharpening cycle maximizes tool life and ensures continued production accuracy. Regular maintenance helps achieve the highest number of re-sharpenings.

Q. Can Super Tools handle custom broach profiles?

Yes, Super Tools specializes in re-sharpening both standard and custom-profile broaches. Our precision grinding equipment can restore intricate and complex tooth geometries. Every custom broach is handled with care to ensure accurate cutting performance. This allows clients with specialized tooling to maintain production quality without replacing expensive custom broaches.

Q. How do I know if a broach needs re-sharpening?

Super Tools recommends re-sharpening when surface finish deteriorates, cutting forces increase, or dimensional accuracy drops. Visual inspection may reveal chipped or worn teeth. Regular monitoring of tool performance helps schedule timely maintenance. Our team can also advise when a broach is nearing the end of its usable life.

Q. Can re-sharpening improve surface finish?

Yes, re-sharpening with Super Tools restores the sharpness of cutting edges, which directly improves the surface finish of machined parts. It reduces tool marks and ensures smoother contact with the workpiece. Improved surface finish also contributes to better dimensional accuracy and part quality.

Q. Broach re-sharpening services in India?

Super Tools provides professional broach re-sharpening services in India, restoring worn cutting edges while maintaining the original tooth geometry. Our precision grinding process improves surface finish, reduces cutting forces, and extends the overall life of your broaches. We ensure dimensional accuracy and consistent performance, helping manufacturers minimize downtime and tooling costs. With Super Tools, you get a reliable and cost-effective solution for high-quality broaching operations across India.