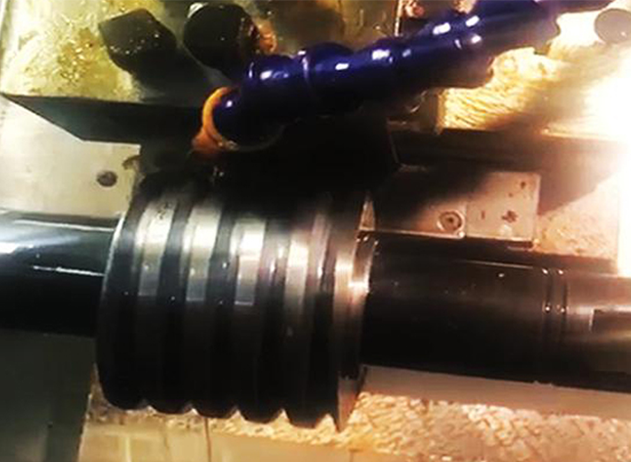

CNC Hob Threading Machine

CNC Hob Threading enables detailed evaluation of thread pitch, profile accuracy, surface finish, and repeatability, supporting high accuracy hob threading requirements. The machine also supports feasibility studies and custom hob threading service for customer-specific applications. By maintaining this machine in-house, Super Tools ensures practical process knowledge, faster technical response, and improved alignment with customer quality expectations. This capability highlights Super Tools’ commitment to technical excellence, advanced high accuracy hob threading, and strong customer collaboration across diverse gear manufacturing applications.

Key Features: –

Advanced CNC Control System

Equipped with a user-friendly CNC controller for precise control of spindle speed, feed rate, pitch, and threading depth.

High Accuracy Threading

Ensures uniform pitch and excellent surface finish with micron-level precision.

Rigid Machine Structure

Heavy-duty cast iron bed minimizes vibration and ensures long-term stability.

Servo-Driven Axes

High-precision servo motors provide smooth motion, high positioning accuracy, and repeatability.

Automatic Threading Cycle

Reduces manual intervention, improves productivity, and ensures consistent output.

Wide Range of Thread Pitches

Capable of producing various thread sizes and profiles as per customer requirements.

Easy Setup & Operation

Intuitive interface allows fast job setup and minimal operator training.

Low Maintenance Design

Built with high-quality components for long service life and reduced downtime.

Customization & Capability

- Customizable maximum hob diameter and length to suit specific production requirements

- Wide range of thread pitches and thread profiles as per customer drawings

- Suitable for single-start and multi-start thread machining

- Choice of CNC control systems such as Fanuc, Siemens, or equivalent

- Variable spindle speed and torque configuration for different materials

- Servo-driven axes for high accuracy, smooth motion, and repeatability

- High-precision threading with excellent surface finish and pitch control

- Capability to machine HSS, alloy steel, tool steel, and semi-hardened materials

- Optional automation including automatic loading and unloading systems

- Custom fixtures, mandrels, and tooling solutions available

- Supports manual, semi-automatic, and fully automatic operation modes

- Heavy-duty rigid construction for vibration-free performance

- Designed for batch production as well as continuous mass production

- Optional full safety enclosure, chip guards, and interlock protection

- Low maintenance design suitable for long-term industrial use