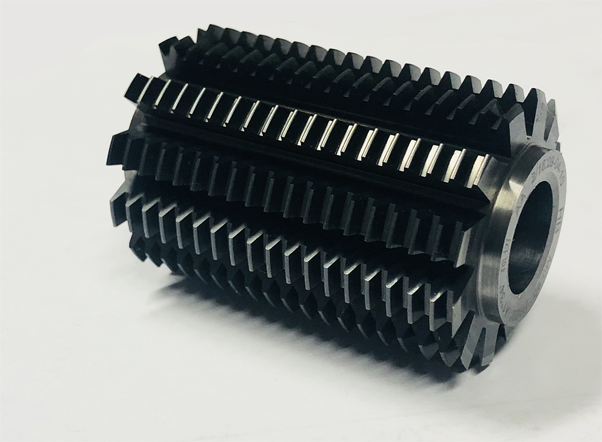

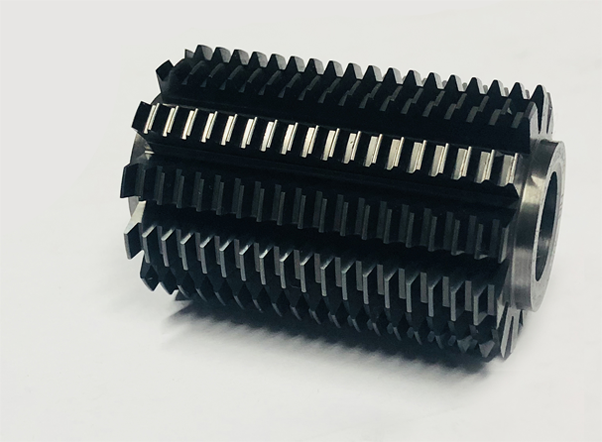

Solid Carbide Hobs

Each Grade has different compositions depending on its final application. Each grade features a specific composition tailored to its final application, ensuring optimized performance across automotive, gearbox, and precision gear manufacturing industries. These hobs deliver high productivity and consistent accuracy even while machining high-hardness components.

Advanced carbide grades support stable performance in both dry and wet machining conditions. Consistent quality helps reduce downtime and improves overall gear production efficiency. STC manufacture customized solid carbide hobs tailored to specific gear parameters and production requirements. Custom modules, lead angles, bore sizes, coatings, and tolerances can be supplied to match OEM specifications. This flexibility ensures optimal cutting performance for specialized applications.

Technical Specification

| SOLID CARBIDE HOBS | |

|---|---|

| Module | 0.1 to 4.0 module |

| Size and Profile | As per customer requirement |

Product FAQ’s

Q. Do Solid Carbide Hob Cutters come with coatings?

- Yes, solid carbide hob cutters are available with advanced coatings such as TiN, TiAlN, and AlCrN.

- These coatings reduce friction, improve wear resistance, and increase cutting speed.

- Coated hob cutters deliver longer tool life and consistent performance in high-production applications.

Q. Are carbide hob cutters available for metric and inch standards?

Yes, carbide hob cutters are available in both metric and inch standards to meet global gear manufacturing requirements. They are produced in various pitches, modules, and dimensions suitable for different systems. This flexibility ensures accurate gear cutting across diverse machines and applications.

Q. Can carbide hob cutters be customized?

Yes, carbide hob cutters can be customized to specific gear profiles, pitches, and dimensions required by the customer. Manufacturers can also tailor features like coatings, tolerance levels, and helix angles. Customized carbide hobs help achieve precise cutting performance for unique or specialized gear applications.

Q. What is the typical lead time for carbide hob cutters?

The typical lead time for carbide hob cutters is usually 4–8 weeks depending on the complexity, size, and customization requirements. Standard sizes may be available faster from stock, while special profiles and coatings can extend the delivery time. Lead times also vary by manufacturer capacity and order volume.

Q. Do you supply carbide hob cutters to OEMs?

As a Top Carbide Hob Cutter Manufacturer in India, our tools are supplied to OEMs and exporters across worldwide markets. Our carbide hobs comply with strict quality, performance, and international export standards, making them reliable for global manufacturing applications.

Q. Do your tools meet international gear manufacturing standards?

Yes, our tools meet international gear manufacturing standards followed across global industries. They are produced with precise geometry, controlled tolerances, and strict quality checks. This ensures consistent performance, accuracy, and reliability in worldwide manufacturing environments.

Q. What tolerances are achievable with carbide hob cutters?

Carbide hob cutters offer very high precision and can achieve tight gear tolerances with excellent consistency. With proper machine rigidity and accurate setup, tooth profile and lead variations are controlled within a few microns. This results in smooth gear finish, reliable performance, and repeatable accuracy in mass production.

Q. Which industries commonly use carbide hob cutters?

- Carbide hob cutters are widely used in the automotive industry for high-precision gears, transmission components, and EV driveline parts.

- They are commonly applied in industrial machinery and gearbox manufacturing where high productivity and tool life are critical.

- Carbide hobs are also used in aerospace, robotics, and heavy engineering industries for cutting hardened and high-accuracy gear profiles.

Q. Are carbide hob cutters suitable for interrupted cutting?

Yes, carbide hob cutters are suitable for interrupted cutting due to their high hardness and wear resistance. Advanced carbide grades with proper edge geometry and coatings help absorb cutting shocks and reduce chipping. Correct machine rigidity, cutting parameters, and tool design are essential to ensure stable performance in interrupted cuts.

Q. Can carbide hob cutters be used on multi-axis CNC hobbing machines?

Yes, carbide hob cutters can be effectively used on multi-axis CNC hobbing machines. Their high rigidity and thermal stability support high-speed, multi-axis synchronized cutting operations. They are ideal for complex gear profiles, automation, and high-precision CNC gear production environments.

Our Range of Carbide Hob Cutters

Solid Carbide

Hobs

STC Manufacture high-performance Solid Carbide Hobs, which can be used in a shell...

Carbide Shank Type Hobs

STC produces Carbide Shank Type Gear Hobs with high functional tool life. Lead angles up to 45°...

Carbide Serration Hobs

We manufacture solid Carbide Serration Hobs with fine pitch as per customer requirements...

Ratchet

Hobs

Carbide Micro Hobs

We are a Manufacturer of Carbide Micro Hobs, used to cut gears having small refined micro gear...

Carbide Special Profile Hobs

We are a Manufacturer of Carbide Special Profile Hob for various components like missing teeth...