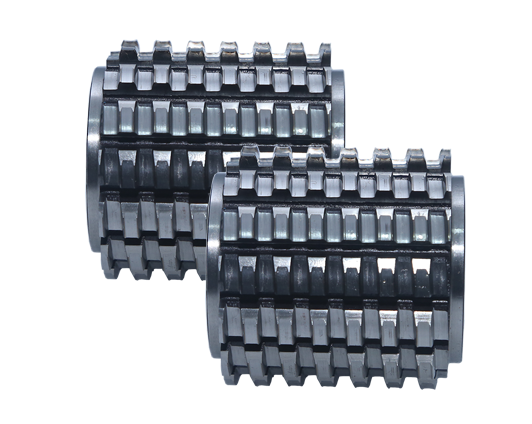

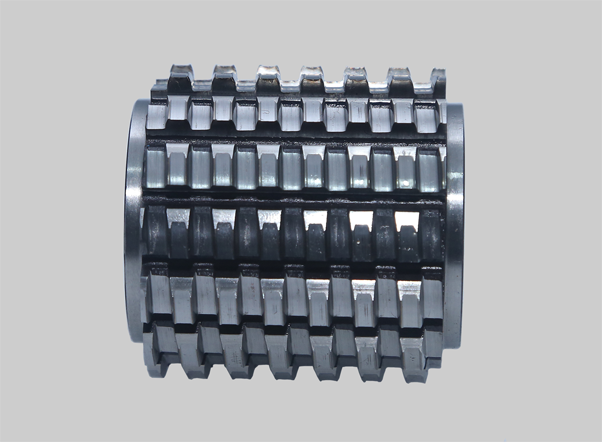

Spline Hobs

With advanced manufacturing facilities and technical expertise, we are always ready to develop custom Spline Hobs as per customer drawings, specifications, and application requirements.

Technical Specification

| SPLINE HOB | |

|---|---|

| Materials | S390/ ASP2052/ ASP2030/ S290/ ASP2060/ M35/ M42/ M2 |

| Accuracy class | AAA, AA, A & B as per DIN3968 |

| Standard | DIN 5480, DIN 5482, ANSI B92.1, B92.2, BS3550, GOST-6033 |

| PVD | Supplied with all types of latest PVD Coatings. |

| Types of Hobs | Spline, Trapezoidal, Involute |

Product FAQ’s

Q. What types of splines can be cut using HSS spline hobs?

HSS spline hobs can cut involute splines, straight splines, and special profile splines. They support both metric and inch spline standards. Custom tooth forms can also be produced based on drawings. This flexibility makes them suitable for diverse industries.

Q. What drawings are required for manufacturing spline hobs?

Spline drawings with module, number of teeth, pressure angle, and profile details are required. Material specifications may also be needed. Tolerance and standard references improve accuracy. Clear drawings ensure precise tool manufacturing.

Q. How many times can an HSS spline hob be reground?

HSS spline hobs can be reground multiple times depending on design. Regrinding maintains profile accuracy if done correctly. This reduces tooling cost significantly. It improves overall cost efficiency.

Q. How does pressure angle affect spline performance?

- Load capacity: A higher pressure angle increases tooth strength and load-carrying capacity, making splines suitable for heavy-duty applications.

- Contact & alignment: Lower pressure angles provide smoother engagement and better alignment but reduce load capacity.

- Wear & noise: Higher pressure angles can increase radial forces, leading to more wear and noise if not properly aligned.

Q. Are left-hand and right-hand spline hobs available?

Yes, both left-hand and right-hand spline hobs are available. Selection depends on machine direction. Correct hand ensures smooth cutting. This avoids tool damage.

Q. What spline profiles can be produced with HSS spline hobs?

HSS spline hobs can produce straight splines, involute splines, serrations, and special profiles. Custom profiles are achievable with engineered hob designs. Profile accuracy remains consistent across batches. This ensures interchangeability of parts.

Q. Can HSS spline hob cutters be reground?

Yes, HSS spline hobs can be reground multiple times. Regrinding restores cutting edges and profile accuracy. This reduces tooling cost per component. Professional regrinding maintains original geometry.

Q. What are the sustainability benefits of HSS spline hobs?

HSS spline hobs are recyclable and support multiple regrinds. This reduces material waste and tooling consumption. Long service life lowers environmental impact. They support sustainable manufacturing practices.

Q. What industries use precision HSS spline hob cutters?

- Automotive & EV manufacturing – Used for producing high-accuracy splines in transmission shafts, gearboxes, steering systems, and electric drive components.

- Aerospace & defense – Applied in aircraft actuators, landing gear systems, and precision power transmission parts requiring tight tolerances.

- Industrial machinery & heavy engineering – Commonly used for splined shafts in machine tools, construction equipment, agricultural machinery, and power transmission assemblies.

Q. Can HSS spline hob cutters be customized for OEM requirements?

Yes, Super Tools Corporation provides HSS Spline Hob Cutters for industrial and OEM applications, as per customer’s requirements. We manufacture precision spline hobs using high quality HSS materials. Our tools are suitable for automotive, gearbox, and transmission manufacturing.

Our Range of HSS Hob Cutters

Gear Hobs

STC is a Manufacturer of Gear Hobs made with maximum accuracy and proper finishing.

Spline Hobs

We are a Manufacturer of Spline Hobs, in Standard and specific customer requirements.

Accuracy class:

Sprocket Hobs

We can also manufacture Chain Sprocket Hobs as per customer requirements or drawings.

Accuracy Class:

Timing Pulley Hobs

We are a Manufacturer of Timing Pulley Hobs in high quality as per ANSI, BS, IS, or any other...

Accuracy :

Worm Hobs

Serration Hobs

We are a Manufacturer and Exporter of Serration Hobs, which are used for generating gears of maximum...

Special Profile Hobs

Besides Standard Gear Hobs, we also Manufacture Special Profile for various components like missing...