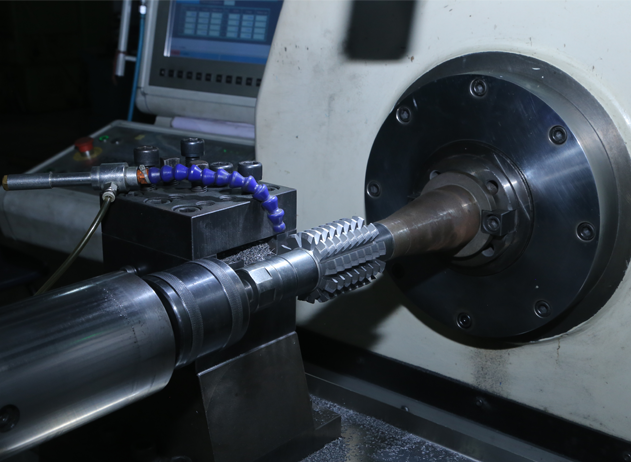

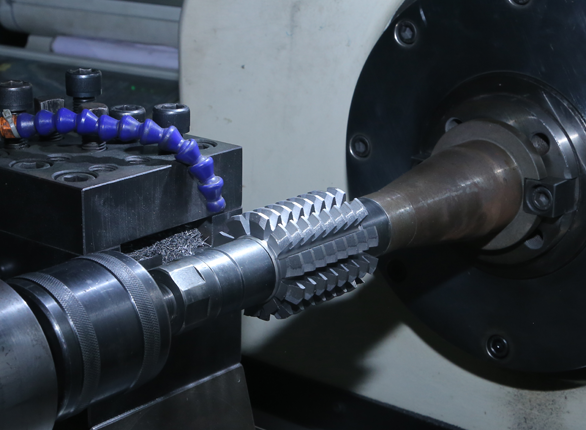

CNC Hob Relieving Lathe Machine

Our CNC relieving capability ensures reliable performance, dimensional accuracy, and production-ready tools trusted by industrial customers. Customers benefit from improved cutting efficiency, reduced tool wear, and dependable performance in high-volume production environments. The CNC Hob Relieving Lathe Machine at Super Tools enhances productivity by delivering stable, repeatable results aligned with modern gear manufacturing standards.

Benefits for Our Valued Customers

Faster turnaround time due to in-house CNC Hob Relieving Lathe Machine, enabling Super Tools to complete relieving operations without external dependency or production delays.

Improved hob cutting efficiency as accurately relieved profiles support smoother gear cutting operations.

High dimensional accuracy maintained throughout the relieving process, supporting tight tolerance requirements demanded by automotive, gearbox, and precision engineering applications.

Capability to handle standard, special, and custom hob profiles, allowing customers to meet specific application needs without compromising quality or performance.

Reduced overall tooling cost over time, as consistent relief quality lowers rework, rejects, and frequent tool replacement.

Reliable and repeatable results that help customers maintain stable production quality, machine uptime, and confidence in every hob supplied by Super Tools.

Core Applications:

- CNC hob relieving for new hob manufacturing, ensuring accurate relief profiles that support efficient cutting performance and long service life.

- Precision relieving of hobs used in automotive, gearbox, and transmission component manufacturing where consistent tooth form and accuracy are critical.

- Custom hob relieving for special gear profiles, module variations, and application-specific designs as per customer drawings and requirements.

- Industrial gear production support for high-volume manufacturing environments requiring repeatable quality and stable tool performance.

- Relief turning for hobs used in heavy engineering, machine tools, and precision mechanical assemblies.

- Support for OEM and aftermarket hob applications where controlled relief geometry directly impacts gear quality and productivity.