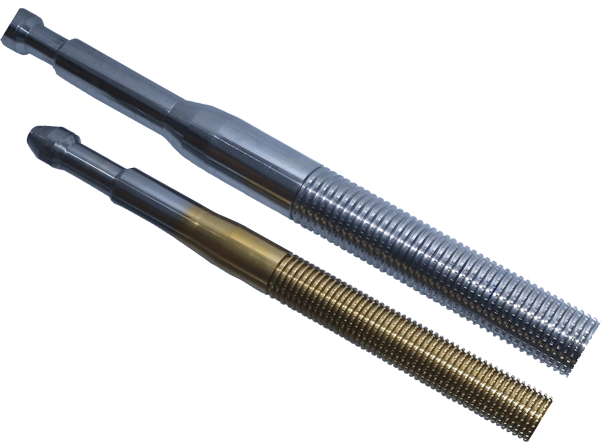

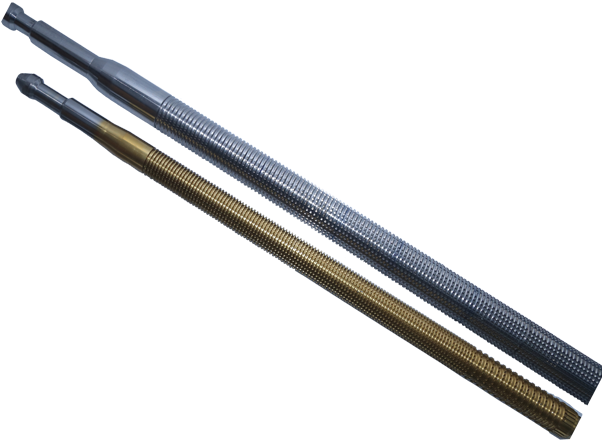

Serration Broaches

These Serration Broaches ensure high dimensional accuracy and consistent tooth profile across large production volumes. Advanced heat treatment and precision grinding improve wear resistance and tool life. They are suitable for automotive, industrial transmission, and heavy engineering applications. Strict quality control is followed to meet international export and performance standards. STC technical support is provided for selection, application, and customization needs. OEM customization, special coatings, and export-ready packaging are also available to meet specific customer and global market requirements. Each broach is tested for profile accuracy and performance to ensure reliable operation in demanding production environments.

Technical Specification

| SERRATION BROACHES | |

|---|---|

| Material | HSS M2, M35, M42, ASP 2030, ASP 2052, ASP 2060. |

| Type | Push Type and Pull Type |

| Heat Treatment Hardness | 64 – 67HR |

| Coating | TiN, TiCN, ALTiN |

| Standards | DIN5481, SMMT 111, HES, ZGN, DBN |

| Max. Od | 280mm |

| Max. Length | Up to 2000mm |

Product FAQ’s

Q. Can you make custom serration broaches as per drawing?

Yes, we manufacture custom serration broaches strictly as per customer drawings or component samples. Tooth profile, pitch, serration depth, material grade, and tolerance are precisely engineered to match application requirements. Each broach is quality-checked to ensure accurate serration form, long tool life, and consistent production performance.

Q. Do you export serration broaches worldwide?

Yes. Super Tools manufactures high-precision serration broaches in India and exports them worldwide to OEMs and industrial buyers. Each broach is produced under strict quality control to meet international standards and application demands.

Q. How do I select the right serration broach for my component?

To select the right serration broach, you should consider the serration profile, pitch, depth, and tolerance required for your component. Material type, hardness, and production volume also play a key role in choosing the correct broach design and tool material.

Q. What is the difference between internal and external serration broaches?

Internal serration broaches are designed to cut serrations inside a bore or hole, commonly used for hubs and internal fittings. External serration broaches are used to form serrations on the outer diameter of shafts or components. The main difference lies in tool design, cutting direction, and application geometry.

Q. What is the functional purpose of serrations produced by broaching?

Serrations produced by broaching provide a positive mechanical lock between mating components, ensuring accurate torque transmission and anti-slip performance. They help maintain precise alignment under load and improve repeatability in assembly.

Q. What broach length is required for deep serration profiles?

The broach length for deep serration profiles depends on serration depth, number of teeth, and required cutting stages. Deeper serrations need longer broaches to allow gradual material removal and proper chip clearance. Stroke length and machine capacity are also considered to ensure stable cutting and accuracy.

Q. What types of serration broaches are available?

STC Serration broaches are available as internal, straight, involute, and special profile types. They can be designed as push or pull broaches depending on machine configuration. Tooth forms may be straight-sided or crowned as per application needs. Customized variants are common for OEM-specific components.

Q. Which industries commonly use serration broaches?

Serration broaches are widely used in automotive, aerospace, heavy engineering, and industrial machinery sectors. They are ideal for components requiring torque transmission and precise alignment. Common applications include shafts, hubs, gears, and couplings. High-volume manufacturing industries prefer broaching for speed and consistency.

Q. What export standards do serration broaches comply with?

STC Export-quality serration broaches comply with international dimensional and material standards. Manufacturing follows strict quality control and inspection procedures. Tools are supplied with proper documentation and packaging. Compliance ensures acceptance by global OEMs and industrial buyers.

Our Range of Broaches

Involute Spline Broaches

STC manufactures Involute Spline Broaches; besides manufacturing Spline Broaches...

Serration Broaches

We are a Manufacturer of Serration Broaches that is designed to be used individually or as a coupling...

Straight Spline Broaches

We are a Manufacturer of Straight Spline Broaches per world standards like DIN and JIS...

Round Broaches

We are a Manufacturer of a large selection of Round Broaches for use in various applications...

Keyway Broaches

We are a Manufacturer of Keyway Broaches, available in Inch and Metric sizes...

Square Broaches

We are a Manufacturer of Square Broaches, also known as “square hole broaches...

Helical Broaches

STC is Manufacturer of Helical Broaches to get the maximum helix angle accuracy ...