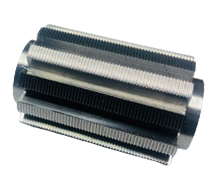

Carbide Shank Type Hobs

These hobs ensure excellent dimensional accuracy and consistent gear tooth profiles during production. Advanced carbide grades provide superior wear resistance and thermal stability for demanding machining conditions. They are suitable for both dry and wet cutting operations across various gear materials.

Hobs are offered with Topping & Non-Topping, Semi-Topping, and Finishing Forms. We also offer customized Carbide Shank Type Hobs manufactured strictly as per customer requirement and drawings. In addition, we export carbide shank type gear hobs worldwide, ensuring consistent quality, reliable performance, and dependable supply to meet global customer demands.

Technical Specification

| CARBIDE SHANK TYPE HOBS | |

|---|---|

| Module | 0.1 to 4.0 module |

| Size and Profile | As per customer requirement |

Product FAQ’s

Q. Which gears can be cut using a carbide shank hob?

Carbide shank hobs are suitable for cutting spur gears, helical gears, and spline shafts with consistent accuracy. They are commonly used for external gear manufacturing in automotive and industrial transmissions. Their rigidity allows reliable machining of high-precision gears in high-speed production.

Q. What modules are available in carbide shank hobs?

Available in fine to coarse modules, typically ranging from 0.1 up to 6.0 module, with higher or special modules available on request. Carbide shank hobs can also be manufactured as per customer drawings, gear parameters, and specific application requirements to meet diverse production needs.

Q. Do you offer standard or customized carbide shank hobs?

Yes, both standard and customized carbide shank hobs are offered to meet different machining needs. Standard designs cover common modules and gear profiles, while customized carbide shank hobs can be developed as per drawings, special profiles, coatings, and specific production requirements.

Q. Which industries use carbide shank type gear hobs?

Carbide shank type gear hobs are widely used in the automotive, industrial gearbox, aerospace, robotics, and precision engineering industries. They are ideal for high-speed, high-accuracy gear production in mass manufacturing as well as specialized component applications.

Q. Can carbide shank hobs be re-sharpened?

Yes, carbide shank hobs can be re-sharpened multiple times depending on wear and application. Proper re-grinding restores cutting accuracy, extends tool life, and helps reduce overall tooling costs when performed using recommended grinding practices.

Q. Are carbide shank hobs suitable for cutting hardened materials?

Yes, carbide shank hobs are well-suited for cutting hardened materials. Their solid carbide construction offers very high hardness and hot strength, allowing efficient machining of heat-treated steels and alloy steels typically up to 55–62 HRC.

Q. What factors affect the performance of carbide shank type hobs?

The performance of carbide shank type hobs depends on the carbide grade and coating quality, which control wear resistance, heat stability, and tool life during high-speed cutting. Machine rigidity, spindle accuracy, and proper tool clamping are critical to prevent vibration and ensure consistent gear accuracy.

Q. Are carbide shank hobs suitable for automotive gear manufacturing?

Yes, carbide shank hobs are highly suitable for automotive gear manufacturing. Their high rigidity and wear resistance support high-speed, high-volume production of transmission, differential, and engine gears with excellent accuracy and surface finish.

Q. Are carbide shank hobs effective for small-diameter and narrow-face gears?

Yes, carbide shank hobs are very effective for small-diameter and narrow-face gears. Their compact shank design allows easy access to confined cutting areas, while solid carbide rigidity ensures stable cutting with minimal deflection. This results in high dimensional accuracy, fine surface finish, and consistent quality even in micro-module and precision gear applications.

Our Range of Carbide Hob Cutters

Solid Carbide

Hobs

STC Manufacture high-performance Solid Carbide Hobs, which can be used in a shell...

Carbide Shank Type Hobs

STC produces Carbide Shank Type Gear Hobs with high functional tool life. Lead angles up to 45°...

Carbide Serration Hobs

We manufacture solid Carbide Serration Hobs with fine pitch as per customer requirements...

Ratchet

Hobs

Carbide Micro Hobs

We are a Manufacturer of Carbide Micro Hobs, used to cut gears having small refined micro gear...

Carbide Special Profile Hobs

We are a Manufacturer of Carbide Special Profile Hob for various components like missing teeth...