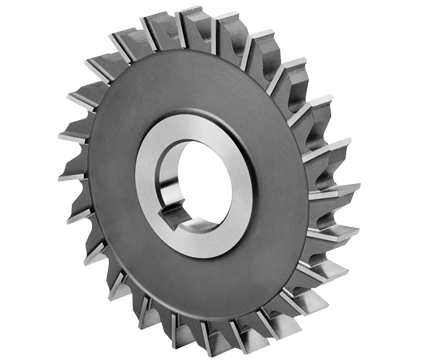

Side and Face Milling Cutter

We also manufacture Slitting Cutters from high-grade materials, ensuring long tool life and a sturdy structure.

Our Side and Face Milling Cutters deliver excellent cutting performance, dimensional accuracy, and smooth surface finish. They are widely used for slotting, grooving, and contour milling operations across multiple industries. Precision heat treatment enhances wear resistance and cutting stability. These cutters are suitable for high-speed and heavy-duty machining applications. Custom sizes, tooth forms, and coatings are available as per customer requirements. Export-quality manufacturing ensures consistent performance and reliability.

Technical Specification

| SIDE AND FACE MILLING CUTTER | |

|---|---|

| Material | HSS M2 & M35 |

| Minimum Diameter | 50 mm |

| Maximum Diameter | 250 mm |

| Coating | Supplied with all types of Coatings. |

| We also manufacturer as per customer’s requirement. | |

Product FAQ’s

Q. What is a Side and Face Milling Cutter?

A side and face milling cutter is a versatile cutting tool designed to machine slots, grooves, and profiles with both side and peripheral cutting edges. It enables high material removal rates with excellent dimensional accuracy. These cutters are commonly used for heavy-duty milling operations. They are suitable for horizontal and vertical milling machines.

Q. What are the types of Side and Face Milling Cutters available?

Side and face milling cutters are available in straight tooth, staggered tooth, and helical tooth designs. They are manufactured in HSS, carbide tipped, and solid carbide variants. Tooth forms vary based on cutting force and surface finish requirements. Selection depends on application, material, and machine capability.

Q. What materials can be machined using Side and Face Milling Cutters?

These cutters can machine carbon steel, alloy steel, stainless steel, cast iron, and non-ferrous metals. Carbide versions handle hardened and high-strength materials efficiently. Tool material selection ensures optimal tool life and finish. Proper cutting parameters maximize performance across materials.

Q. Can Side and Face Milling Cutters be customized as per drawing?

Yes, side and face milling cutters can be customized based on customer drawings and machining requirements. Custom tooth profiles, widths, and bore sizes are possible. Special coatings and materials can be applied. Customization improves productivity and component accuracy.

Q. What export standards and quality compliances are followed?

Side and face milling cutters are manufactured in compliance with ISO and international machining standards. Quality inspections ensure dimensional accuracy and hardness consistency. Export packaging meets international logistics requirements. Compliance guarantees reliability in global markets.

Q. How are Side and Face Milling Cutters installed correctly?

The cutter should be mounted on a suitable arbor with correct spacers and clamping force. Alignment with the spindle axis is critical. Proper tightening prevents vibration during operation. Trial runs ensure safe and stable cutting performance.

Q. How should Side and Face Milling Cutters be maintained?

Regular cleaning and inspection help maintain cutting performance. Re-sharpening restores cutting edges and extends tool life. Proper storage prevents corrosion and edge damage. Scheduled maintenance reduces downtime and tooling costs.

Q. What coatings are available for Side and Face Milling Cutters?

Common coatings include TiN, TiAlN, and AlCrN for improved wear resistance. Coated cutters offer longer tool life and better heat resistance. Coatings reduce friction during cutting. Selection depends on workpiece material and cutting conditions.

Q. Are Side and Face Milling Cutters suitable for high-volume production?

Yes, they are ideal for high-volume and continuous production environments. High material removal rates improve cycle times. Robust tooth design supports long production runs. They deliver consistent dimensional accuracy in mass manufacturing.

Q. What information is required to order a custom Side and Face Milling Cutter?

Required details include cutter diameter, width, bore size, tooth form, and material. Application details and workpiece material are important. Machine specifications help optimize design. Accurate inputs ensure optimal cutter performance.

Our Range of Milling Cutters

Form Milling Cutter

STC is a Manufacturer of Form Milling Cutters. We have a experts team in designing & manufacturing...

Rack Milling Cutter

We are a Manufacturer of Rack Milling Cutters, made in Single or multiple rows with Straight...

Involute Gear Cutter

We are a Manufacturer of Involute Gear Cutters. The bright finish coating on the cutting edges...

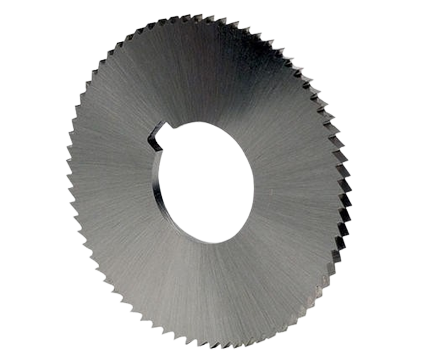

HSS Slitting Saw Cutter

We provide an extensive range of Slitting Cutters, which are ideal for metalworking applications...

Side and Face Milling Cutter

We are a Manufacturer of Side and Face Cutter, which made in various diameters depending on usage...

Solid Carbide Milling Cutter

STC is a Manufacturer and Exporter of Solid Carbide Milling Cutters, generally used in CNC machining...