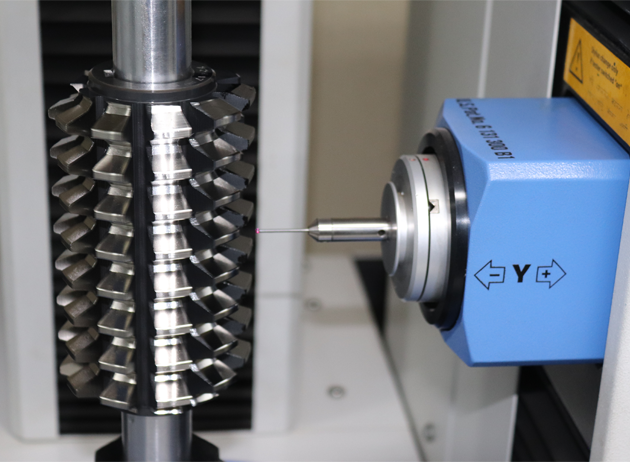

CNC Gear Tester

At Super Tools, our factory infrastructure is the backbone of our commitment to precision, consistency, and global quality standards. With decades of manufacturing expertise, we operate a modern, well-equipped production facility dedicated to the manufacture of gear cutting tools, spline gauges, and master gears for demanding industrial applications worldwide.

Our infrastructure is designed to support high accuracy manufacturing, stringent quality control, and reliable export supply, making Super Tools a trusted partner for OEMs and gear manufacturers across global markets.

- Modern gear tool manufacturing infrastructure

- CNC Lead & Profile inspection on Klingelnberg P26

- Proven expertise in gear cutting tools and gauges

- Export-focused production and quality systems

- Custom manufacturing capability

- Trusted by global gear manufacturers

State-of-the-Art Manufacturing Facility

Our Manufacturing Capabilities Include:

- CNC gear cutting tool manufacturing systems

- Dedicated production lines for gear hobs, gear shaper cutters, and gear shaving cutters

- Precision machining facilities for spline gauges and master gears

- Controlled grinding and finishing processes for superior surface quality

- In-house tooling and fixture development for custom requirements

This strong infrastructure allows us to handle standard, special, and custom-engineered gear tools with consistent quality.

CNC Gear Testing & Inspection Excellence

Gear Inspection on Klingelnberg P26:

We inspect:

- Gear hobs

- Gear shaper cutters

- Gear shaving cutters

- Spline gauges

- Master gears

Using the Klingelnberg P26, we accurately measure:

- Profile deviation

- Lead deviation

- Pitch errors

- Runout and tooth alignment

- Total composite errors

This ensures every tool meets international gear accuracy standards before dispatch.

Export-Ready Manufacturing & Global Supply Capability

Export Capabilities:

- Consistent batch quality for overseas customers

- Export-standard inspection reports

- Safe and secure packaging for international transit

- OEM and private labeling support

- Timely dispatch and logistics coordination

Our infrastructure supports long-term global partnerships with gear manufacturers, automotive suppliers, and industrial OEMs.

Custom Manufacturing & Special Tool Development

We specialize in:

- Special module and pressure angle tools

- Custom spline profiles and tolerances

- Prototype and small batch development

- Repeat production with documented accuracy

This flexibility makes Super Tools a preferred choice for customers requiring non-standard or high-precision gear solutions.