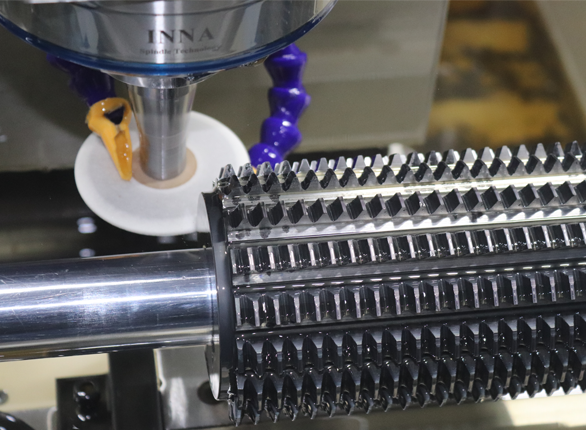

CNC Hob Sharpening Machine

Technical Specification

| CNC Hob Sharpening Machine |

|---|

| Maximum length: 300mm |

| Sharpening Quality of “AAA” Class |

| Increased Production |

CNC Hob Sharpening Machine Benefits: –

Precision Sharpening

Ensures ultra-accurate gear tooth profiles and consistent cutting edges for optimal hob performance.

Reduced Cycle Time

CNC automation speeds up sharpening compared to manual methods, increasing throughput.

Consistent Quality

Programmable CNC controls deliver repeatable sharpening results with minimal variation.

Extended Tool Life

Properly ground hobs last longer, reducing tooling costs and downtime.

Enhanced Gear Accuracy

Sharpened hobs maintain gear accuracy, improving end-product quality.

Lower Labor Dependency

CNC reduces reliance on skilled manual operators and lowers human error risk.

Flexible & Programmable

Supports multiple hob types, sizes, and geometries through programmable setups.

Better Surface Finish

Improved hob edge quality results in smoother gear surfaces during cutting.

Cost-Effective Maintenance

Regular sharpening cuts replacement expenses and maximizes ROI.

Automation & Feedback

Advanced CNC machines offer diagnostic feedback and automated adjustments for process optimization.

Customization & Capability

- Supports wide range of hob sizes, modules, and pressure angles.

- Custom sharpening programs developed as per hob design and gear application.

- Super Tools’ CNC-controlled profile correction restores original tooth geometry with precision.

- Adjustable sharpening parameters for material type and cutting conditions.

- Accurate re-sharpening with minimal material removal to extend tool life.

- Super Tools ensures consistent results across single-piece, batch, and bulk sharpening jobs.

- Ability to correct profile errors, pitch deviations, and edge wear.

- Supports OEM specifications and customer-defined tolerances.

- Ideal for both production regrinding and tool-room applications.

- Flexible setup ensures repeatability, accuracy, and process reliability.

- With Super Tools’ expertise, custom solutions can be tailored to your specific gear production requirements.