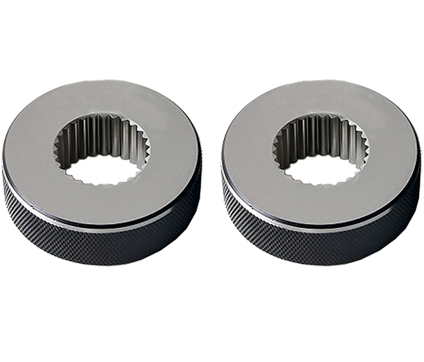

Spline Gauges

Our spline gauges ensure high accuracy, repeatability, and long service life in demanding inspection environments. Precision manufacturing guarantees consistent results for quality control and production inspection. Custom designs are available as per customer drawings and international standards.

Spline Plug Gauges can be manufactured and supplied in following profiles:

- Involute Spline

- Straight Spline

- Serration

Product FAQ’s

Q. What are spline gauges and why are they used?

Spline gauges are precision inspection tools used to check the accuracy of internal and external splines. They verify tooth profile, pitch, pressure angle, and fit according to specified standards. Spline gauges ensure interchangeability and functional performance of mating components. They are essential for quality control in spline manufacturing and assembly.

Q. What types of spline gauges are available?

Spline gauges are available as Go and No-Go gauges for pass–fail inspection. Common types include plug gauges for internal splines and ring gauges for external splines. Master spline gauges are used for calibration and reference purposes. Special profile and segment spline gauges are also available for complex applications.

Q. What technical standards do spline gauges follow?

Spline gauges are manufactured according to international standards such as ISO, DIN, ANSI and JIS. These standards define tooth form, tolerance class, fit, and inspection limits. Compliance ensures global interchangeability and consistent quality verification. Custom gauges can also be produced as per customer drawings and specifications.

Q. What materials are used for manufacturing spline gauges?

Spline gauges are typically manufactured from high-grade tool steels or alloy steels. Materials are heat-treated to achieve high hardness and wear resistance. Proper material selection ensures dimensional stability over long inspection cycles. Surface finishing improves gauge life and measurement consistency.

Q. What industries commonly use spline gauges?

Spline gauges are widely used in automotive transmission and drivetrain manufacturing. Aerospace industries rely on them for critical spline inspection and safety compliance. Heavy engineering, agricultural machinery, and industrial gear manufacturing also use spline gauges. They are essential wherever spline accuracy directly affects performance.

Q. Can spline gauges be customized as per drawings?

Yes, spline gauges can be fully customized according to customer drawings and spline data. Parameters such as module, number of teeth, pressure angle, and tolerance class can be specified. Both standard and non-standard spline forms can be manufactured. Customization ensures precise inspection for unique component designs.

Q. How are spline gauges installed and used?

Spline gauges require no complex installation and are used directly on the component. The Go gauge should pass smoothly, while the No-Go gauge should not enter fully. Cleanliness of both gauge and component is essential for accurate inspection. Proper handling avoids damage and ensures reliable results.

Q. How should spline gauges be maintained?

Spline gauges should be cleaned after each use to remove oil and debris. They must be stored in dry, protected conditions to prevent corrosion. Periodic calibration ensures continued accuracy and reliability. Proper maintenance significantly extends gauge service life.

Q. How do spline gauges ensure component interchangeability?

Spline gauges verify compliance with defined fit and tolerance standards. This ensures parts from different batches or suppliers mate correctly. Interchangeability improves assembly efficiency and reduces downtime. It is critical for global supply chains and OEM requirements.

Our Range of Gauges

Spline Gauges

Spline Plug Gauges can be manufactured in following profiles:

Spline Plug Gauges can be manufactured in following profiles:

Involute Spline

Straight Spline

Spline Ring Gauges

Go Ring Gauges

Master or set Ring Gauges