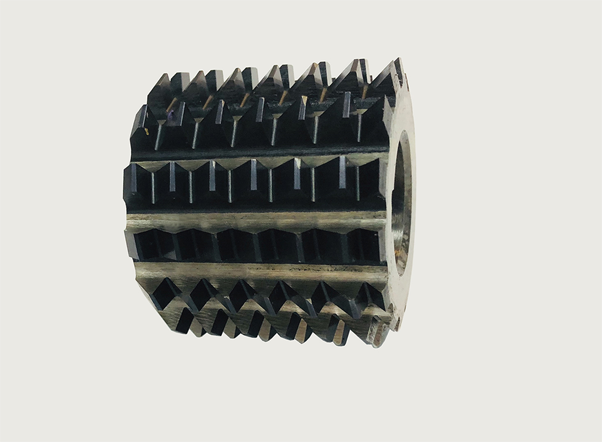

Ratchet Hobs

Ratchet Hobs ensure high accuracy and consistent gear profiles during finishing operations. They improve surface finish while maintaining tight dimensional tolerances. Advanced tool design supports stable cutting and extended tool life. Suitable for high-volume and precision gear manufacturing applications. Manufactured with strict quality control to ensure reliable and repeatable performance. Ratchet Hobs enable controlled gear finishing with high process stability. They are suitable for both medium and large batch production requirements.

We provide all materials and size ranges based on the customer’s specific drawings and size. Ratchet can be considered as the alternative method of finishing gears by shaving.

Product FAQ’s

Q. Is a ratchet hob different from a gear hob?

Yes, a ratchet hob is different from a gear hob because it is designed to cut asymmetric, one-directional ratchet teeth rather than symmetrical gear teeth. Ratchet hobs create locking or indexing profiles instead of continuous power transmission. Gear hobs are used for smooth rotary motion, while ratchet hobs focus on controlled movement and holding functions.

Q. What is the typical module or DP range of ratchet hob?

Modules and DP are fully customized as per ratchet wheel specifications, ensuring precise tooth geometry and accurate engagement. The hob design is developed strictly according to drawings, samples, or functional requirements. This flexibility allows reliable performance across light-duty to heavy-duty ratchet applications.

Q. Do you manufacture ratchet hobs as per drawing?

Yes, ratchet hobs are manufactured strictly as per customer drawings or samples to ensure accurate tooth profile and function. All critical parameters such as module or DP, tooth form, pressure angle, and dimensions are precisely controlled. This ensures perfect matching with the ratchet wheel and reliable performance in application.

Q. Who manufactures export quality ratchet hobs in India?

Super Tools Corporation is a trusted Indian manufacturer of export-quality ratchet hobs, supplying OEMs and exporters worldwide. The company follows strict quality control, precision manufacturing, and international standards to meet global requirements. Custom designs, consistent accuracy, and reliable performance make it a preferred choice in overseas markets.

Q. What information is required to manufacture a ratchet hob?

To manufacture a ratchet hob accurately, details such as ratchet wheel drawing or sample, module or DP, number of teeth, and tooth profile are required. Additional information includes pressure angle, outside diameter, bore size, face width, and material to be cut. Operating conditions like cutting speed, machine type, and production volume further help optimize the hob design.

Q. Which industries use ratchet hobs?

Ratchet hobs are widely used in the automotive industry for parking, locking, and adjustment mechanisms. They are also used in industrial machinery, hand tools, and material handling equipment for indexing and holding functions.

Q. Can solid carbide ratchet hobs be designed for special tooth profiles?

- Yes, solid carbide ratchet hobs can be precisely designed for special tooth profiles based on customer drawings, samples, or application requirements.

- Customized tooth geometry ensures accurate engagement, smooth ratchet action, and consistent load distribution.

Q. Can solid carbide ratchet hobs be re-sharpened or reconditioned?

Yes, solid carbide ratchet hobs can be re-sharpened and reconditioned using precision CNC grinding while maintaining the original tooth profile. Proper reconditioning restores cutting performance, improves tool life, and reduces overall tooling cost.

Q. Do solid carbide ratchet hobs provide better surface finish on ratchet teeth?

Yes, solid carbide ratchet hobs provide a significantly better surface finish on ratchet teeth due to their high rigidity and sharp cutting edges. They ensure smooth material removal, reduced vibration, and minimal burr formation during cutting.

Q. Can solid carbide ratchet hobs be designed for asymmetric tooth profiles?

Yes, solid carbide ratchet hobs can be precisely designed for asymmetric tooth profiles to meet specific load direction and engagement requirements.

Our Range of Carbide Hob Cutters

Solid Carbide

Hobs

STC Manufacture high-performance Solid Carbide Hobs, which can be used in a shell...

Carbide Shank Type Hobs

STC produces Carbide Shank Type Gear Hobs with high functional tool life. Lead angles up to 45°...

Carbide Serration Hobs

We manufacture solid Carbide Serration Hobs with fine pitch as per customer requirements...

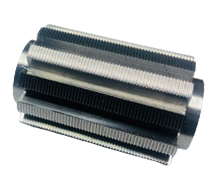

Ratchet

Hobs

Carbide Micro Hobs

We are a Manufacturer of Carbide Micro Hobs, used to cut gears having small refined micro gear...

Carbide Special Profile Hobs

We are a Manufacturer of Carbide Special Profile Hob for various components like missing teeth...