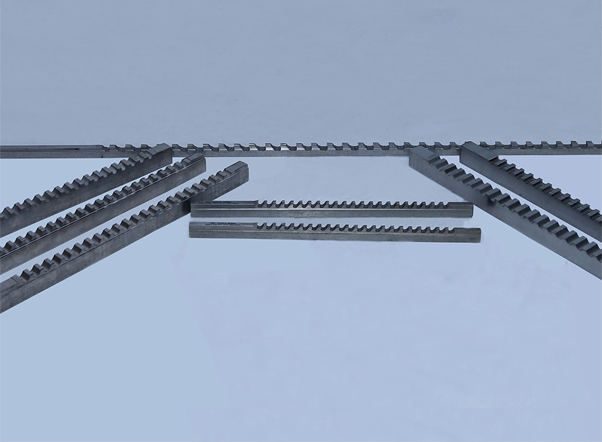

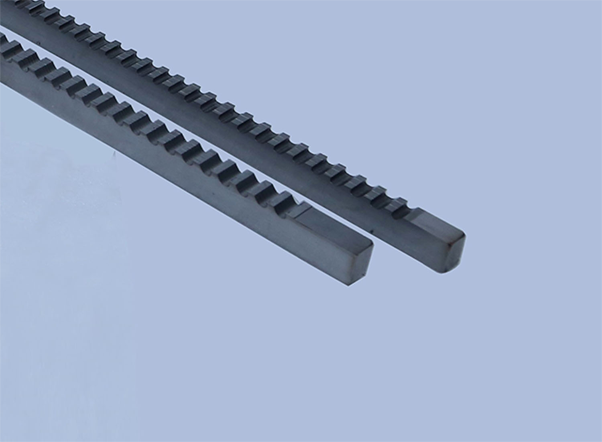

Keyway Broaches

These are suitable for materials such as Cast Iron, Steel, Brass, and aluminum. Keyway Broaches Sets are also available.

They ensure smooth keyway cutting with minimal burrs, reducing finishing time. Custom sizes and profiles can be manufactured to meet specific customer requirements. These broaches are durable, providing long tool life even under heavy usage. They are ideal for both production workshops and precision engineering environments. We also offer complete Keyway Broach Kits, including accessories for easy setup and operation. All our products comply with international quality standards, ensuring reliable performance across worldwide.

Technical Specification

| KEYWAY BROACHES | |

|---|---|

| Material | HSS M2, M35 |

| Length | up to 1.6 meter |

| Broach Length | 127mm to 515 mm |

| Type | Push and Pull Type |

| Keyway Broach with Shims | |

Product FAQ’s

Q. How does a keyway broach work?

A keyway broach works by being pushed or pulled through a pre-drilled hole, where its progressively taller teeth remove material step by step to form the keyway. As the broach moves forward, each tooth cuts a small amount of metal, gradually shaping the slot to the required size. This process produces a precise, straight keyway with good dimensional accuracy and surface finish in a single operation.

Q. What are the types of keyway broaches?

Keyway broaches are available in standard types such as straight keyway broaches for common parallel keys, square keyway broaches for heavy-duty torque transmission, and hex or special-profile broaches for non-standard applications. They are also classified as push-type or pull-type depending on the machine used. Custom keyway broaches are manufactured as per specific key sizes, tolerances, and component requirements.

Q. Are metric and inch keyway broaches both available?

At Super Tools, both metric and inch keyway broaches are available to suit international standards and machine requirements. Metric broaches are commonly used for ISO and DIN key sizes, while inch broaches are designed for ANSI and imperial standards. Manufacturers also offer custom keyway broaches to match specific drawings, tolerances, and application needs.

Q. What information is required to order a keyway broach?

To order a keyway broach, details such as keyway width, depth, and length are required along with the bore diameter of the component. Material of the workpiece, tolerance requirements, and whether a metric or inch standard is needed should also be specified. Information about the broaching method (push or pull) and machine capacity helps ensure correct tool selection.

Q. What is the maximum length available for Keyway Broaches?

Keyway broaches can be manufactured with an overall length of up to 1.6 meters. This allows machining of deep and long keyways. Longer broaches ensure stable cutting action. They are suitable for large components and heavy-duty use.

Q. Can keyway broaches handle interrupted cuts?

Yes, STC keyway broaches can handle interrupted cuts, but tool design and cutting conditions are critical. Interrupted surfaces increase shock loads on the teeth, so broaches are designed with proper tooth geometry, strength, and cutting rise.

Q. What maintenance is required for keyway broaches?

Regular cleaning and proper lubrication extend broach life. Periodic inspection helps identify wear early. Proper storage prevents corrosion and damage. Preventive maintenance reduces downtime and tooling costs.

Q. What defines a high-quality keyway broach?

A high-quality keyway broach has precise width and depth control. Premium tool steel and proper heat treatment ensure durability. Smooth cutting action minimizes vibration. Quality broaches deliver consistent results across batches.

Q. Why are keyway broaches preferred over alternative methods?

Keyway broaches provide better accuracy than milling or slotting. Single-pass cutting saves time and cost. Tool life and consistency are superior. This makes broaching the preferred solution.

Our Range of Broaches

Involute Spline Broaches

STC manufactures Involute Spline Broaches; besides manufacturing Spline Broaches...

Serration Broaches

We are a Manufacturer of Serration Broaches that is designed to be used individually or as a coupling...

Straight Spline Broaches

We are a Manufacturer of Straight Spline Broaches per world standards like DIN and JIS...

Round Broaches

We are a Manufacturer of a large selection of Round Broaches for use in various applications...

Keyway Broaches

We are a Manufacturer of Keyway Broaches, available in Inch and Metric sizes...

Square Broaches

We are a Manufacturer of Square Broaches, also known as “square hole broaches...

Helical Broaches

STC is Manufacturer of Helical Broaches to get the maximum helix angle accuracy ...