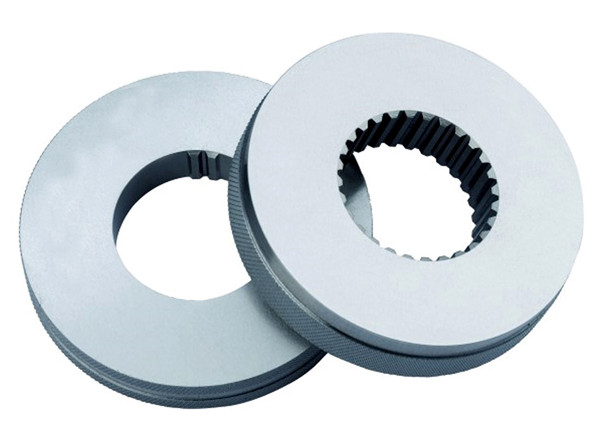

Spline Ring Gauges

The gauges deliver high accuracy and repeatability for reliable quality control in production environments. Precision machining ensures consistent fit and long service life. They are suitable for automotive, aerospace, gearbox, and industrial transmission applications. Custom sizes, tolerances, and finishes can be provided to meet specific inspection needs. Export-grade quality and standards compliance ensure dependable global usage.

Product FAQ’s

Q. What types of spline ring gauges are available?

Spline ring gauges are available as GO and NO-GO gauges for functional inspection. They can be manufactured for involute, straight-sided, serration, or special spline profiles. Gauges may be supplied as single-piece or segmented designs depending on size. Metric, inch, and customized spline standards are supported.

Q. What technical specifications define spline ring gauges?

Key specifications include module or DP, number of teeth, pressure angle, and tolerance class. Gauges are manufactured to standards such as ISO, DIN, ANSI, or customer drawings. Material hardness and surface finish ensure dimensional stability. Accuracy is maintained through controlled heat treatment and grinding processes.

Q. Do spline ring gauges have load-bearing capacity?

Spline ring gauges are inspection tools and not designed for mechanical load transmission. They are used only to check fit, alignment, and spline geometry. Proper handling ensures accuracy without inducing stress or wear. Their strength supports repeated gauging cycles under controlled conditions.

Q. Can spline ring gauges be customized as per drawings?

Yes, spline ring gauges can be fully customized based on customer drawings or spline data. Special tolerances, profiles, and inspection conditions can be incorporated. Markings, calibration data, and identification details can be added. Custom designs ensure compatibility with specific components and standards.

Q. Which export standards and compliances are followed?

Spline ring gauges are manufactured in compliance with ISO, DIN, ANSI, and customer-specific standards. Calibration is traceable to national or international measurement systems. Export packaging meets international shipping and corrosion protection norms. Documentation supports global quality and audit requirements.

Q. How should spline ring gauges be installed and used?

No installation is required, as spline ring gauges are handheld inspection tools. Components should be clean before gauging to avoid false readings. The gauge should slide smoothly without force during inspection. Proper use ensures consistent and repeatable measurement results.

Q. What maintenance is required for spline ring gauges?

Regular cleaning after use prevents debris buildup and surface damage. Gauges should be lightly oiled and stored in protective cases. Periodic recalibration ensures long-term accuracy and compliance. Proper maintenance significantly extends tool life and reliability.

Q. How do spline ring gauges compare to spline plug gauges?

Spline ring gauges inspect external splines, while plug gauges check internal splines. Both ensure functional fit but serve different component geometries. Ring gauges are ideal for shafts and male splines. Selecting the correct gauge improves inspection efficiency and accuracy.

Q. Can spline ring gauges be used for incoming inspection?

Yes, spline ring gauges are widely used for incoming quality checks. They verify supplier components before production use. This ensures conformity to specified spline standards. Incoming inspection reduces supply chain quality risks.

Q. What are spline ring gauges and why are they used?

Spline ring gauges are precision inspection tools used to verify the external splines of shafts. They ensure correct fit, tooth profile, and dimensional accuracy as per specified standards. These gauges help control manufacturing quality and reduce assembly issues. They are widely used in automotive, aerospace, and industrial transmission components.

Technical Specification

| SPLINE RING GAUGES | |

|---|---|

| Quality Standard | Involute Spline ANSI B 92.1-1970 |

| Range | dia 19mm-dia 130mm with 25mm profile length. |

Our Range of Gauges

Spline Gauges

Spline Plug Gauges can be manufactured in following profiles:

Spline Plug Gauges can be manufactured in following profiles:

Involute Spline

Straight Spline

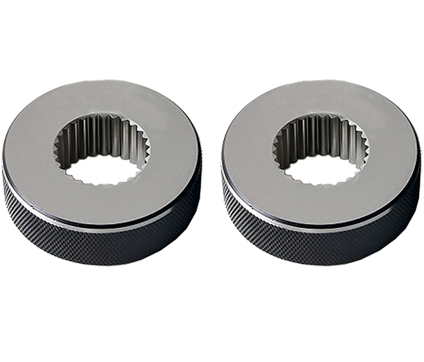

Spline Ring Gauges

Go Ring Gauges

Master or set Ring Gauges