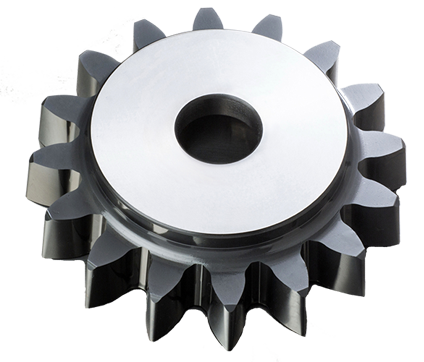

Special Profile Shaper Cutter

Our cutters are manufactured using high-grade materials to ensure accuracy, durability, and consistent performance. Advanced machining and inspection processes are followed to meet industrial precision standards. Multiple coating options are offered to enhance tool life and cutting efficiency. These shaper cutters are suitable for diverse applications across tool rooms, workshops, and production units. We support OEM and bulk orders with reliable quality and timely dispatch.

Technical Specification

| SPECIAL PROFILE SHAPER CITTER | |

|---|---|

| Material | HSS M2, M35, M42, ASP30, ASP52, S390 and Solid Carbide |

| Accuracy Class | ‘AA’ & ‘A’ as per DIN 1829 |

| Coating | TiN, TiAlN coating |

| Gear Type | Internal & External |

| PVD Coating | All types of PVD coating as per requirement. |

Product FAQ’s

Q. What cutter materials are used in Special Profile Shaper Cutters?

Common materials include HSS, M2, M35, M42, and powder metallurgy steels.

Solid carbide options are available for high wear resistance.

Material selection depends on cutting speed and production volume.

Heat treatment improves hardness and tool life.

Q. What coatings are available for Special Profile Shaper Cutters?

Super Tools Corporation offers optional coatings such as TiN, TiAlN, and AlCrN for Special Profile Shaper Cutters to enhance cutter performance. These advanced coatings reduce friction and significantly improve wear resistance during machining. As a result, tool life is extended, especially in high-volume production environments. Coated cutters also help achieve better surface finish and consistent cutting quality.

Q. What load capacity can a Special Profile Shaper Cutter handle?

Load capacity depends on cutter design, material, and tooth geometry.

Heavier profiles require reinforced cutter bodies.

Cutting forces are calculated during design stage.

This ensures safe operation under industrial production loads.

Q. Special Profile Shaper Cutters are suitable for CNC and conventional machines?

Yes, Super Tools Corporation designs cutters for both CNC and conventional shaping machines. Tool geometry is optimized based on machine rigidity and speed. Proper design ensures smooth cutting performance. This flexibility supports diverse manufacturing setups.

Q. Who is a reliable manufacturer of Special Profile Shaper Cutters in India?

Super Tools Corporation is a reliable manufacturer of Special Profile Shaper Cutters in India. The company is known for quality manufacturing, precision profiles, and consistent performance for industrial machining applications.

Q. How should a Special Profile Shaper Cutter be installed?

A Special Profile Shaper Cutter should be mounted securely with precise alignment and firm clamping to prevent vibration during operation. Cutting parameters such as speed, feed, and depth of cut must match the tool design and work material specifications. Proper installation ensures machining accuracy, safe operation, and extended tool life.

Q. What is the load capacity of a Special Profile Shaper Cutter?

Load capacity depends on cutter size and material.

Tooth geometry distributes cutting forces evenly.

Proper design prevents tool deflection.

Correct parameters ensure safe operation.

Q. Can Special Profile Shaper Cutters be customized?

Yes, Super Tools Corporation manufactures Special Profile Shaper Cutters that are fully customizable based on drawings or samples. Profile geometry, material, and tolerance can be specified as per application needs. Custom designs help improve machining efficiency and accuracy. OEM-specific solutions are widely supported.

Q. Is installation of Special Profile Shaper Cutters complex?

No, installation is straightforward when proper mounting accessories are used. Correct alignment is essential for accurate profiling. Installation guidelines are provided. This ensures safe and efficient operation.

Q. Can Special Profile Shaper Cutters be re-sharpened?

Yes, most Special Profile Shaper Cutters can be re-sharpened multiple times to restore sharp cutting edges while maintaining the original profile accuracy. Proper re-grinding helps extend tool life, ensures consistent machining performance, and significantly reduces overall tooling costs.

Our Range of Shaper Cutters

Special Profile Shaper Cutter

Besides Standard Shaper Cutters, we also supply Special Profile Shaper Cutters...

Disc Type Shaper Cutter

STC is a Manufacturer of Disc Type Gear Shaper Cutters designed to cut any gear, internal or external...

Shank Type Shaper Cutter

We are a Manufacturer of Shank Type Shaper Cutters, mainly used for cutting internal gears...

Hub Type Shaper Cutter

We are a Manufacturer and Exporter of Hub Type Shaper Cutters...

Helical Shaper Cutter

We are a Manufacturer of Helical Shaper Cutters, having their teeth inclined at a helix angle...

Timing Pulley Shaper Cutter

We are Manufacturer of Timing Pulley Shaper Cutter. These shaper cutters are manufactured...

Chain Sprocket Shaper Cutter

Besides Standard Shaper Cutters, we also provide customized Shaper Cutters as per specific customer...