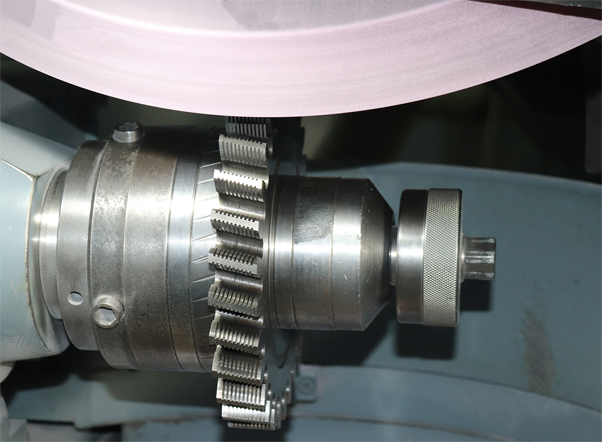

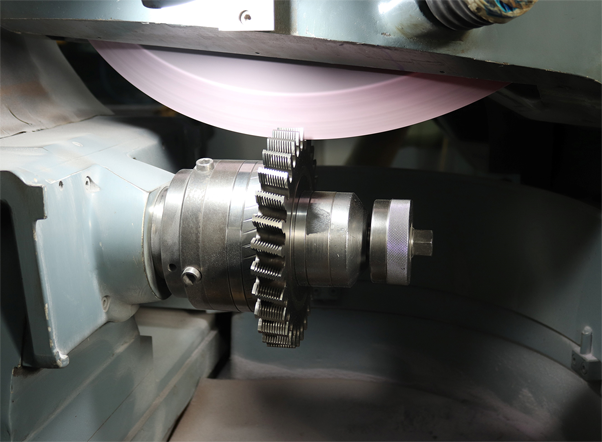

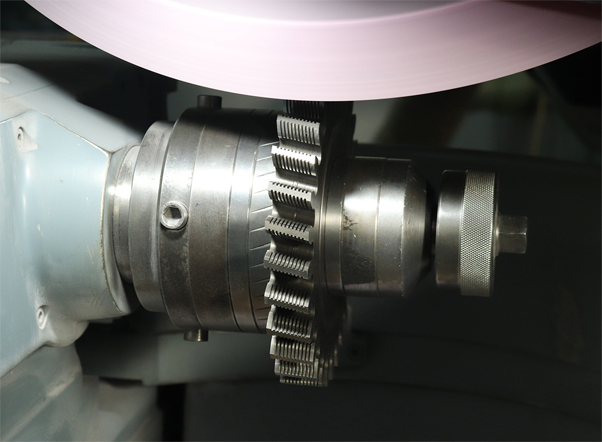

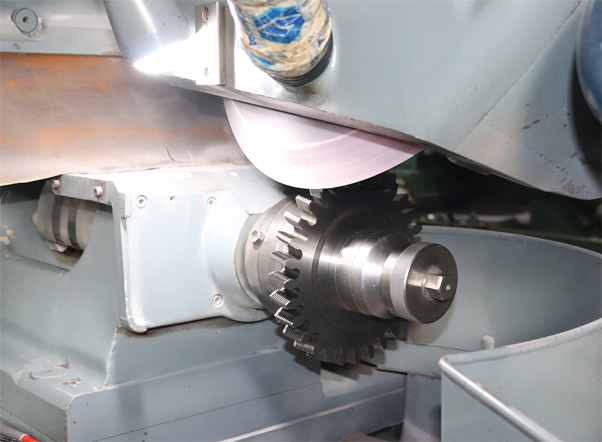

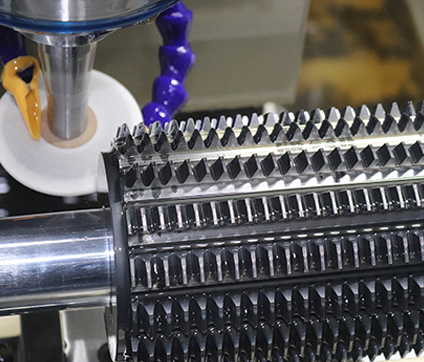

Gear Shaving Cutter Resharpening

The Re-Sharpening of the shaving cutters is provided at very reasonable prices, and your tools will be inspected and sorted, and plastic box packing will be provided for protection.

Trusted Partner for Gear Tool Services

With decades of experience in gear cutting tools and reconditioning services, Super Tools is a reliable partner for gear manufacturers seeking consistent performance and technical expertise. Our gear shaving cutter resharpening services are designed to support high-precision manufacturing environments where accuracy, repeatability, and tool reliability are critical.

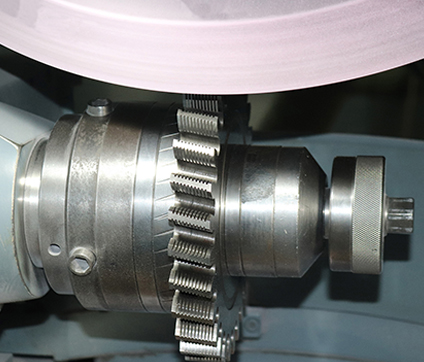

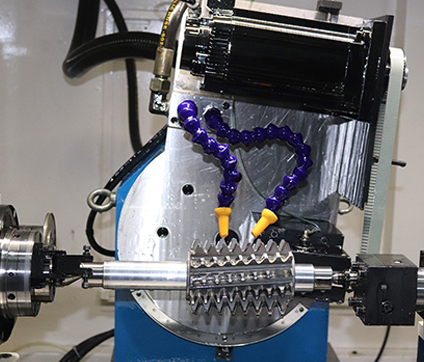

Our Gear Shaving Cutter Resharpening Capabilities

We provide comprehensive resharpening solutions for a wide range of shaving cutters, including:

Our process ensures accurate restoration of cutter profiles, lead, pressure angle, and tooth form.

Commitment to Quality & Precision

At Super Tools, quality is at the core of everything we do. Every resharpened gear shaving cutter undergoes thorough inspection to ensure it meets performance expectations and customer specifications. Our focus is on delivering reliable, repeatable, and precise results that enhance your manufacturing efficiency.

Product FAQ’s

Q. Do you follow OEM specifications during resharpening?

Yes. Our resharpening process adheres to OEM or customer-specified geometries, ensuring restored cutters meet original design and performance requirements.

Q. Do you provide inspection reports?

Yes, inspection and quality verification details can be provided upon request to ensure full transparency and confidence in the resharpened cutter.

Q. Can resharpening improve cutter performance?

Yes. Apart from restoring worn geometry, minor adjustments to rake and clearance angles can optimize cutting efficiency, reducing cutting forces and improving gear surface finish.

Q. What information is required for gear shaving cutter resharpening?

Basic cutter details such as module, number of teeth, and pressure angle are required. Original profile or drawing helps maintain geometry. Current cutter condition is also evaluated. This ensures accurate and controlled resharpening results.

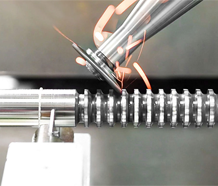

Q. How is tooth profile accuracy checked after resharpening?

Tooth profile accuracy is verified using precision inspection equipment. Profile, lead, and alignment are carefully measured. Any deviation is corrected during grinding. This ensures compliance with gear shaving requirements.

Our Other Services

Hob Cutter Resharpening

Shaving Cutter Resharpening

Master Gear Reprofiling

Hob Cutter Reprofiling

Broach Re-Sharpening