Rack Milling Cutters

Technical Specification

| RACK MILLING CUTTERS | |

|---|---|

| Material | M35, ASP2030, ASP2052, & S390 materials. |

| Accuracy class | Accuracy class up to AA |

| Module Range | 0.5 to 6.0 Module |

| Diameter Range | 50mm to 250mm |

| Coating | Supplied with all types of coatings |

| Can be made with varied pitch. | |

| Can be made for correctual profiles | |

Product FAQ’s

Q. What are Rack Milling Cutters?

Rack milling cutters are precision cutting tools used to machine straight gear racks with accurate tooth profiles. They ensure consistent pitch, tooth depth, and smooth meshing in linear motion systems. These cutters are widely used in gear manufacturing industries.

Q. What modules and pitches are available?

Rack milling cutters are available in a wide range of standard and custom modules and pitches. Both metric and imperial standards can be supported. The range depends on rack size, load requirements, and end-use industry.

Q. Are coated Rack Milling Cutters available?

Yes, coatings such as TiN, TiAlN, and AlCrN are available for rack milling cutters. These coatings reduce friction, improve wear resistance, and extend tool life. Coated cutters are preferred for high-speed and high-volume production.

Q. What modules and pitches are available in Rack Milling Cutters?

Rack milling cutters are available in a wide range of metric and imperial modules and pitches. Both standard and special sizes can be produced. Super Tools Corporation supports custom modules for specialized rack applications.

Q. What industries use Rack Milling Cutters the most?

Automotive, automation, material handling, machine tool, and heavy engineering industries widely use rack milling cutters. Accuracy directly affects system performance. We supplies cutters to global industrial sectors.

Q. Do Rack Milling Cutters support metric and imperial standards?

Yes, both metric and imperial standards are supported. This allows global compatibility. Super Tools Corporation manufactures cutters to international standards.

Q. How accurate are Rack Milling Cutters?

High accuracy in pitch, tooth profile, and surface finish can be achieved. Precision grinding ensures consistent results. We are focuses on tight tolerances for industrial accuracy.

Q. What inspection methods are used for Rack Milling Cutters?

Profile inspection, pitch measurement, and dimensional checks are commonly used. These ensure consistent accuracy. We follows strict inspection procedures.

Q. Are Rack Milling Cutters suitable for international standards?

Yes, they are manufactured to comply with international gear standards. This ensures global acceptance. We supports international compliance.

Q. What is the importance of pitch consistency in rack milling?

Consistent pitch ensures smooth engagement with pinions and prevents backlash. Even small errors can affect performance. Super Tools Corporation maintains strict pitch accuracy in its rack milling cutters.

Our Range of Milling Cutters

Form Milling Cutter

STC is a Manufacturer of Form Milling Cutters. We have a experts team in designing & manufacturing...

Rack Milling Cutter

We are a Manufacturer of Rack Milling Cutters, made in Single or multiple rows with Straight...

Involute Gear Cutter

We are a Manufacturer of Involute Gear Cutters. The bright finish coating on the cutting edges...

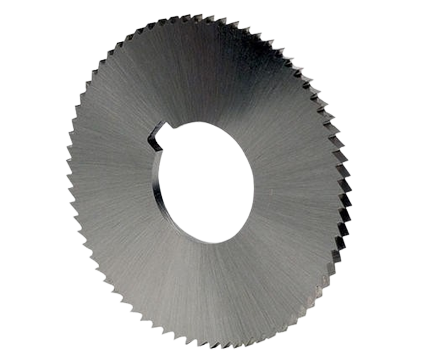

HSS Slitting Saw Cutter

We provide an extensive range of Slitting Cutters, which are ideal for metalworking applications...

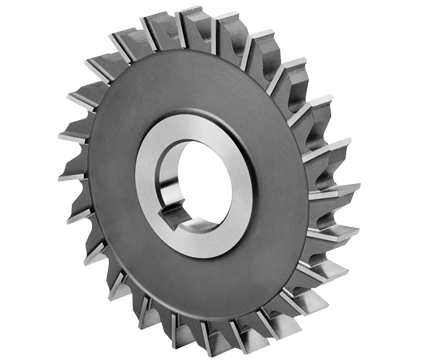

Side and Face Milling Cutter

We are a Manufacturer of Side and Face Cutter, which made in various diameters depending on usage...

Solid Carbide Milling Cutter

STC is a Manufacturer and Exporter of Solid Carbide Milling Cutters, generally used in CNC machining...