PVD Coating

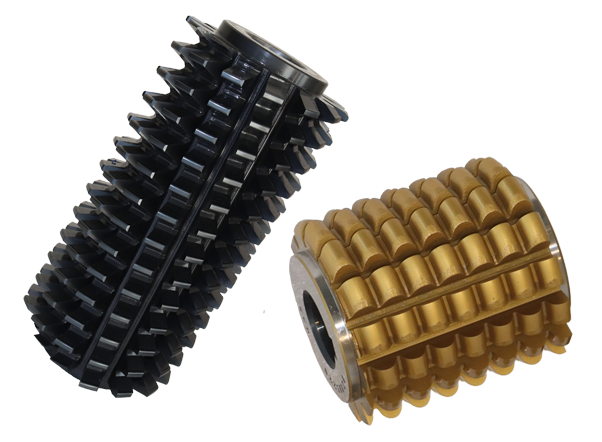

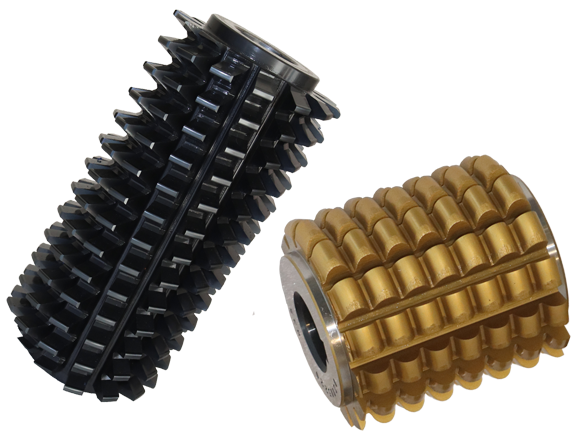

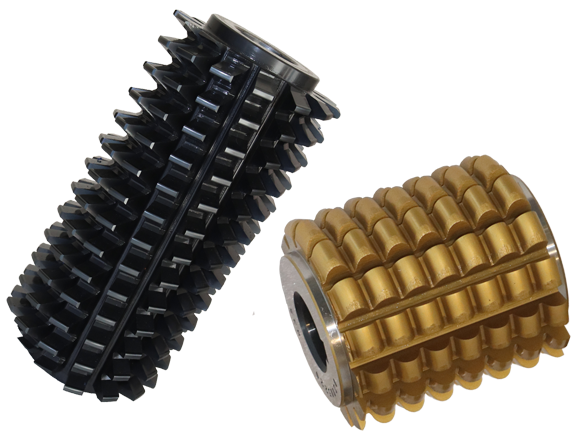

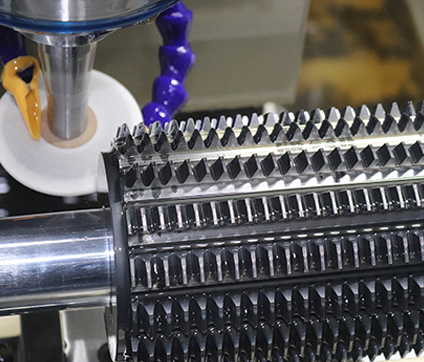

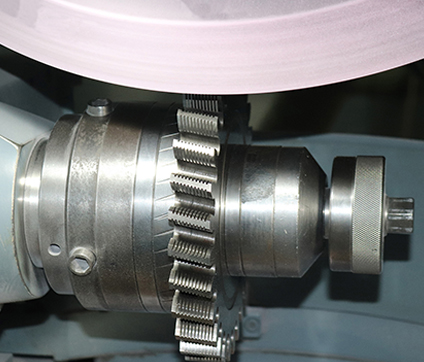

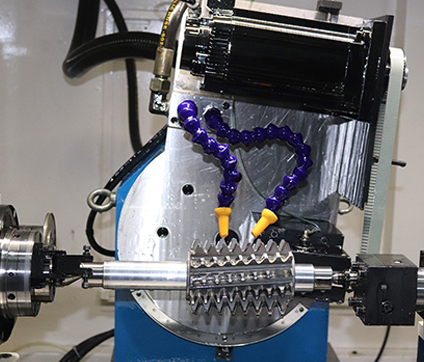

Super Tools Corporation provides advanced PVD Coating (Physical Vapor Deposition) services designed to enhance the performance, durability, and life of industrial cutting tools. Our PVD coatings improve wear resistance, reduce friction, and maintain sharp cutting edges, making them ideal for high-precision and high-speed machining applications.

With controlled coating processes and strict quality checks, we deliver reliable PVD coating solutions for manufacturers seeking consistent tool performance and lower tooling costs.

What is PVD Coating?

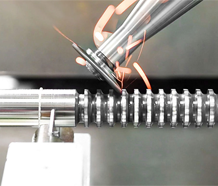

PVD (Physical Vapor Deposition) is a vacuum-based coating process where hard, wear-resistant layers are deposited on tool surfaces at controlled temperatures. The coating forms a thin, uniform layer that significantly improves hardness, oxidation resistance, and thermal stability without affecting tool geometry.

Our PVD Coating Capabilities

Super Tools Corporation offers PVD coatings suitable for a wide range of cutting tools and industrial components.

Tools Suitable for PVD Coating

Our PVD coating services are ideal for:

PVD coating can be applied to HSS, HSS-Co, and solid carbide tools.

Key Benefits of PVD Coating

These benefits make PVD coating essential for high-volume and precision manufacturing.

Quality Control & Process Standards

Super Tools Corporation follows strict process control at every stage of PVD coating. Surface preparation, coating parameters, and post-coating inspection are carefully monitored to ensure uniformity, adhesion strength, and performance consistency. Every batch is inspected to meet international industrial quality expectations.

Why Choose

Super Tools Corporation for PVD Coating?

Product FAQ’s

Q. What types of PVD coatings are available?

Common PVD coatings include TiN, TiAlN, AlTiN, and multi-layer coatings. Each coating is selected based on cutting speed, material, and heat generation. Super Tools Corporation recommends the right coating for your application. This ensures optimal tool performance and durability.

Q. How does PVD coating improve tool life?

PVD coating increases surface hardness and protects tools from abrasive wear. It reduces heat buildup and oxidation during machining. Lower friction improves chip flow and cutting stability. As a result, tools last longer and require fewer replacements.

Q. Is PVD coating suitable for re-sharpened tools?

Yes, PVD coating is ideal for re-sharpened tools after proper surface preparation. Coating restores performance close to that of new tools. Super Tools Corporation combines re-sharpening and PVD coating for maximum cost efficiency. This helps extend the usable life of tools.

Q. What industries benefit most from PVD coated tools?

Automotive, gear manufacturing, aerospace, defense, and heavy engineering industries widely use PVD coated tools. These industries demand high tool life and stable machining performance. PVD coating supports high production volumes. It also improves machining reliability.

Q. Why choose Super Tools Corporation for PVD coating services?

Super Tools Corporation offers controlled PVD coating processes with strict quality checks. We provide coating solutions aligned with cutting tool applications. Reliable turnaround time and technical support add value. Our services help manufacturers reduce tooling costs and improve productivity.

Q. How thick is a typical PVD coating layer?

PVD coatings are extremely thin, typically a few microns thick. The thin layer maintains tool geometry and sharpness. Despite being thin, it offers high hardness and wear resistance. This is ideal for precision machining applications.

Q. Can different PVD coatings be selected for different applications?

Yes, coating selection depends on cutting speed, work material, and operating temperature. TiN is suitable for general machining. TiAlN and AlTiN are preferred for high-speed and dry machining. Super Tools Corporation helps select the right coating.

Q. Does PVD coating support dry and high-speed machining?

Yes, PVD coatings are highly suitable for dry and high-speed machining. They provide excellent thermal stability and oxidation resistance. Reduced friction minimizes heat generation. This improves productivity and machining efficiency.

Q. Does PVD coating improve surface finish of machined components?

Yes, reduced friction and stable cutting edges improve surface finish. PVD coated tools cut smoothly with less vibration. This results in consistent dimensional accuracy. Better finish reduces secondary operations.

Q. Is PVD coating suitable for export-quality tools?

Yes, PVD coating meets international industrial quality expectations. Coated tools are widely accepted in global markets. Consistent coating quality supports export requirements. This makes them suitable for OEM and international buyers.

Our Other Services

Hob Cutter Resharpening

Shaving Cutter Resharpening

Master Gear Reprofiling

Hob Cutter Reprofiling

Broach Re-Sharpening