Power Skiving Tools

STC is a trusted manufacturer of Power Skiving Tools and advanced gear cutting solutions. With a strong legacy of engineering excellence, we design and produce highperformance power skiving cutters, skiving tool sets, and custom skiving tooling that help manufacturers achieve precision, high efficiency, and maximum productivity in gear production. Our Power Skiving Tools are engineered for modern industrial gear machining, delivering superior accuracy, extended tool life, and reliable performance across a wide range of gear types, materials, and production volumes.

What Are Power Skiving Tools?

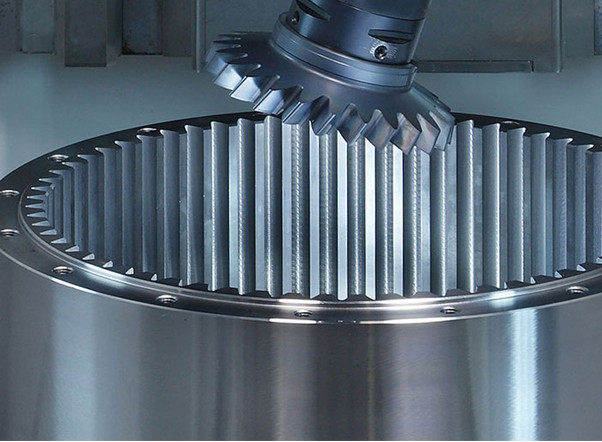

Power Skiving Tools are precision engineered gear cutting tools used for highspeed skiving operations, combining the advantages of hobbing and shaping to produce internal and external gears with exceptional accuracy. “Power Skiving Tools, also known as Gear Skiving Cutters or Power Skiving Cutter, are precision-engineered tools for high-efficiency gear manufacturing.”

Contact us today to explore our product range, request technical specifications, or get a custom power skiving tool solution tailored to your application.

Our Product Range — Precision That Powers Performance

External Gear Skiving Tools

Internal Gear Skiving Tools

Custom Power Skiving Tools

Key Features & Technical Advantages

Precision Gear Cutting — Accurate tooth profiles and consistent runout control.

High Productivity — Shorter cycle times compared to traditional gear shaping and hobbing.

Advanced Coatings & Materials — Premium substrates with highperformance coatings for longer tool life.

Superior Chip Evacuation — Reduces vibration and tool gouging for cleaner cuts.

Versatility — Effective across a range of materials including alloy steels, hardened steels, and nonferrous metals.

Custom Configurations — Tools designed to your gear specifications and production needs.

Why Choose Us?

IndustryProven Quality — Tools built to exacting standards using precision CNC and grinding

Enhanced Production Efficiency — Reduce downtime and machining costs.

Repeatable Accuracy — Meets stringent tolerances and surface finish requirements.

Technical Expertise & Support — Dedicated application engineering and tool optimization assistance

Global Supply & Support — Reliable delivery and service for manufacturers worldwide.

Technical Specification

| Power Skiving Tools | |

|---|---|

| Material | ASP 2052, ASP 2060, S390, S290 and Solid Carbide. |

| Coating | TiAlN & Altensa |

| Profile | Standard and Non-Standard As per drawing. |

| Type | Hub & Shank Type |

Product FAQ’s

Q. What are Power Skiving Tools?

Power Skiving Tools are precision gear cutting tools used to machine internal and external gears efficiently. They combine the advantages of hobbing and shaping to deliver high accuracy and superior surface finish. These tools are designed for high-speed, high-volume production environments. Manufacturers use them to reduce cycle time and improve gear quality consistently.

Q. What types of Power Skiving Tools are available?

Super Tools manufactures External Gear Skiving Tools, Internal Gear Skiving Tools, Custom Skiving Tools, and modular Tool Holders. Each type is engineered for specific gear geometries and materials. External tools cut shafts or discs, internal tools machine inner gear profiles. Custom solutions meet specialized industrial production requirements worldwide.

Q. Can Power Skiving Tools be customized?

Yes, Super Tools offers customized Power Skiving Tools based on gear size, material, tooth profile, and production needs. Customization ensures maximum efficiency, optimal tool life, and reduced machining costs. Our engineering team works closely with clients to deliver tailored industrial gear solutions. These tools meet exact industrial and international standards.

Q. What materials and coatings are used in Power Skiving Tools?

Tools are typically made from premium-grade high-speed steel or carbide alloys for maximum strength. Advanced coatings such as TiN, TiAlN, or DLC enhance wear resistance and heat tolerance. These coatings reduce tool friction, extend lifespan, and improve cutting performance. Material and coating selection depends on gear material and production speed.

Q. What are the load capacities of Power Skiving Tools?

Load capacity varies with tool size, material, and gear type, supporting both medium and heavy-duty operations. Our tools are designed to withstand high axial and radial loads during high-speed cutting. Optimized geometry and coatings prevent deformation and minimize tool wear. Proper selection ensures efficient and reliable gear machining in industrial applications.

Q. Which industries use Power Skiving Tools?

Our tools are widely used in automotive transmission, aerospace gear systems, industrial machinery, robotics, and heavy equipment manufacturing. Super Tools high-precision gear skiving tools improve efficiency, reduce scrap, and enhance overall gear quality. Manufacturers rely on our tools for both high-volume and precision-critical applications.

Q. How are Power Skiving Tools installed and maintained?

Tools should be mounted using precise holders and aligned according to machine specifications. Regular inspection, cleaning, and lubrication prevent wear and maintain accuracy. Worn or damaged tools must be reground or replaced. Following recommended maintenance practices ensures long life and consistent performance.

Q. What is the structure of Power Skiving Tools?

Power Skiving Tools consist of a cutting body with helical teeth, tool shank, and sometimes modular holders. Cutting teeth are precision-ground for high accuracy and smooth gear profiles. Tools may have coatings and fluting for chip removal and heat dissipation. The overall design ensures stability, repeatable performance, and long tool life.

Q. Do you export Power Skiving Tools worldwide?

Yes, Super Tools exports high-quality Power Skiving Tools worldwide, serving manufacturers across Europe, North America, Asia, and the Middle East. We ensure timely delivery, proper packaging, and full compliance with international shipping regulations. Our global clients rely on us for precision, consistency, and reliable supply.

Q. Are your Power Skiving Tools compliant with international standards?

Yes, Super Tools manufactures Power Skiving Tools in compliance with ISO, DIN, and other global quality standards. All tools undergo rigorous testing for precision, durability, and coating performance. This ensures they meet the strict requirements of international clients. Our tools are export-ready for demanding industrial applications worldwide.

Q. What are Power Skiving Tools also called?

Power Skiving Tools are also known as Skiving Cutters, Gear Skiving Tools, or Power Skiving Cutters. They are advanced gear cutting tools used for manufacturing internal and external gears with high precision and efficiency, especially on CNC machines.

Q. What is the role of power skiving cutter manufacture in gear machining?

Power skiving cutter manufacture plays a critical role in modern gear machining by enabling high-precision cutting of internal and external gears with excellent accuracy, surface finish, and reduced cycle time on CNC machines.