Master Gear Re-Profiling

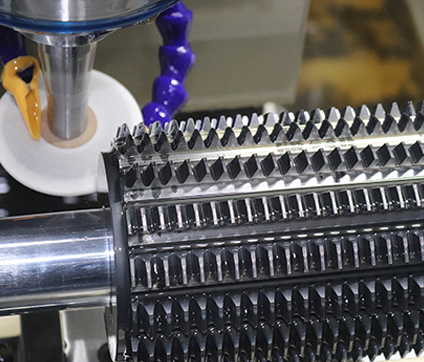

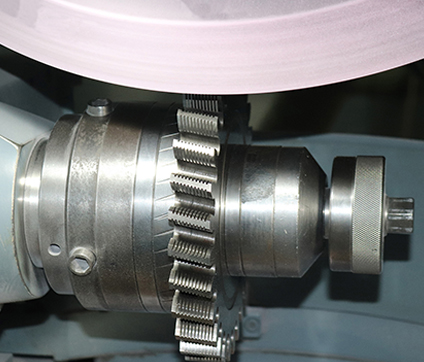

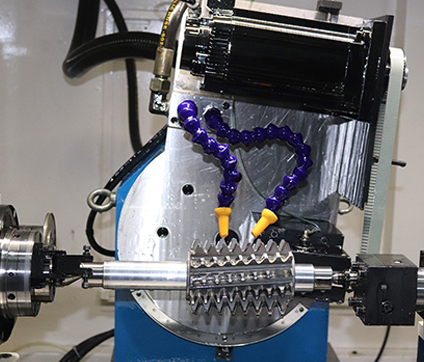

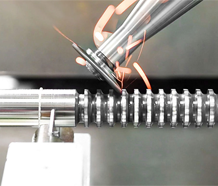

We Re-Profile Master Gears on state-of-the-art Profile Grinding Machines. Profile Correction can be done as per customer requirements. Lead and Profile graphs done on Klingelnberg P26 CNC Tester are provided.

Benefits of Master Gear Re-Profiling

- Cost Savings: Extends the life of expensive master gears.

- Improved Inspection Accuracy: Maintains reliability in gear testing processes.

- Standards Compliance: Ensures alignment with current measurement and manufacturing standards.

- Reduced Lead Times: Faster than manufacturing a new master gear from scratch.

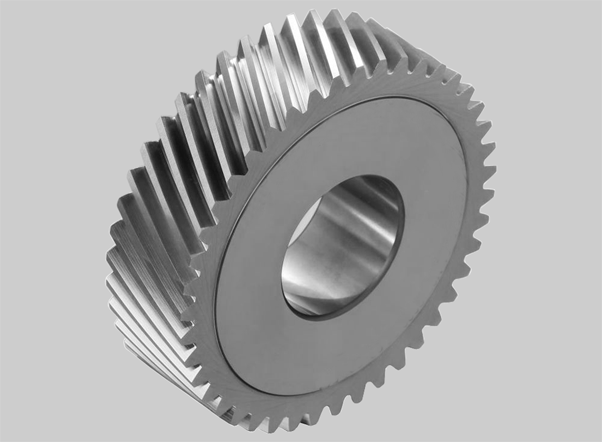

What Is Master Gear Re-Profiling?

Master Gear Re-Profiling is a precision reconditioning process that corrects tooth profile deviations, wear marks, and pitch errors in master gears. Over time, continuous use in inspection systems causes micro-wear that can affect measurement accuracy. Re-profiling restores the involute form, flank geometry, and dimensional precision to meet original inspection requirements.

Our re-profiling process precisely reshapes gear teeth to:

Quality & Precision You Can Trust

Why Choose Super Tools for Master Gear Re-Profiling?

At Super Tools, we combine engineering expertise with advanced machinery to deliver consistent and reliable results.

Key Advantages

Product FAQ’s

Q. When should a master gear be re-profiled?

should be re-profiled when:

- Tooth wear or profile deviation is detected

- Noise or vibration increases during operation

- Measurement inconsistencies occur in production gears

- Periodic recalibration of reference gears is required

Q. Can re-profiling improve gear performance beyond OEM specifications?

Yes. In certain applications, optimized re-profiling can improve load distribution, reduce contact stress, and enhance operational smoothness beyond original OEM profiles.

Q. Which manufacturer provides precision-driven Master Gear Re-Profiling services for industrial applications?

Super Tools delivers precision-driven Master Gear Re-Profiling solutions that keep your operations running smoothly and efficiently.

Q. Can all master gears be re-profiled?

- Not all master gears can be re-profiled.

- Re-profiling is possible only if sufficient material remains and the gear is free from cracks or severe damage.

- A detailed inspection is required to determine feasibility and ensure accuracy.

Q. How many times can a master gear be re-profiled?

A master gear can be re-profiled multiple times, depending on available tooth material and allowable tolerance limits. Each re-profiling removes a small amount of material, so feasibility decreases over time. A precision inspection determines how many re-profiling cycles are safely possible.

Q. Do you provide inspection reports after re-profiling?

Yes, we provide detailed inspection reports after re-profiling. These reports include profile, lead, pitch, and accuracy verification results. They ensure the master gear meets required precision and quality standards.

Q. What types of master gears can be re-profiled?

Master gears used in single flank and double flank inspection systems, gear roll testers, honing machines, and gear measuring equipment can be re-profiled. This includes both cylindrical and pinion master gears used in industrial metrology applications.

Q. Can master gears be re-profiled as per customer drawings or standards?

Yes, re-profiling can be carried out based on customer drawings, original master gear specifications, or specific inspection standards. This ensures compatibility with existing quality control and measurement systems.

Our Other Services

Hob Cutter Resharpening

Shaving Cutter Resharpening

Master Gear Reprofiling

Hob Cutter Reprofiling

Broach Re-Sharpening