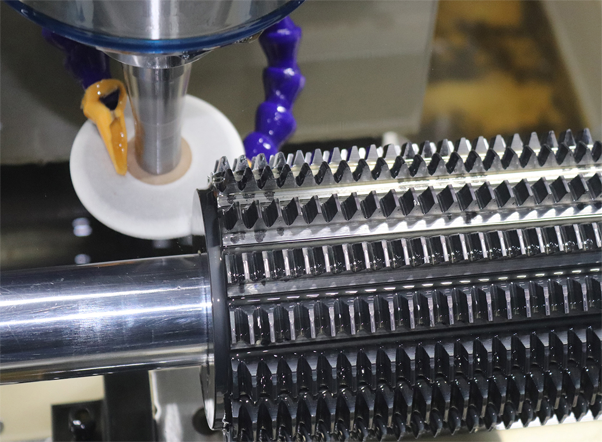

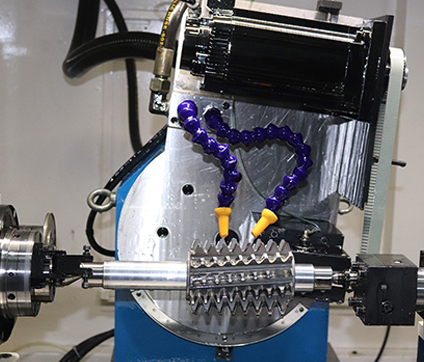

Hob Cutter Resharpening

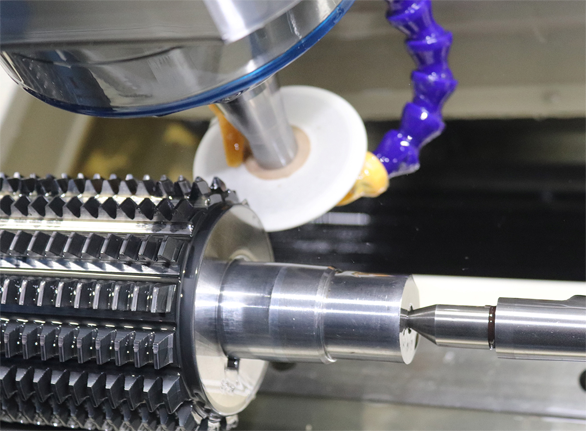

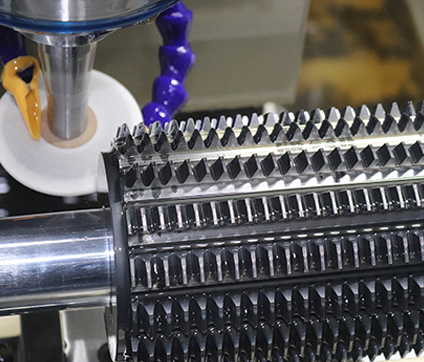

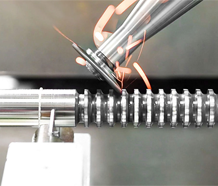

We provide Hob Cutter Re-Sharpening Services. Re-Sharpening of the Hobs is done on state of an art CNC HOB SHARPENING MACHINE which can sharpen Hobs up the “AAA” class. After a hob is used to produce a certain number of gears, the wear is high enough that the gear quality decreases or the risk of significant tool damage rise. At that time, a hob needs to be reconditioned. The tools are Resharp to the original specifications and complete dimensions like new tools.

The maintenance of Hob is a very delicate operation, and skilled operators must carry it out. We provide the best quality Re-Sharpening of tools that maintain productivity.

Why Hob Cutter Re-Sharpening Is Critical

Hob cutters lose sharpness over time due to continuous cutting loads, heat generation, and material wear. Improper or delayed re-sharpening can lead to poor gear accuracy, higher rejection rates, and increased machine downtime. Our re-sharpening service helps you regain original performance without the expense of new tools.

Technical Capabilities & Accuracy

Maintains original hob geometry

Minimal runout and pitch deviation

Suitable for multiple re-sharpening cycles

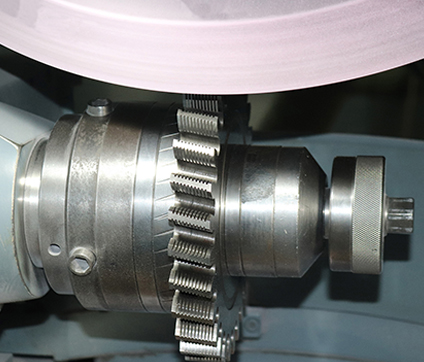

Compatible with CNC and conventional hobbing machines

Quality Control & Standards

At Super Tools, quality control is an integral part of our Hob Cutter Re-Sharpening Services. Our re-sharpening process follows strict internal quality procedures aligned with international gear manufacturing requirements. Inspection data and reports can be provided on request to support OEM and export compliance.

Why Choose Us?

Advanced grinding and inspection equipment

Reliable partner for long-term tool maintenance

Product FAQ’s

Q. What is hob cutter re-sharpening?

Hob cutter re-sharpening is a precision grinding process that restores worn cutting edges of gear hobs. It maintains the original tooth profile and cutting geometry. This helps achieve consistent gear accuracy. Re-sharpening significantly extends tool life.’

Q. What quality checks are performed after re-sharpening?

Each hob undergoes dimensional and visual inspection. Tooth profile, pitch accuracy, lead, and runout are verified. Surface finish is also checked. Inspection reports can be provided on request.

Q. Can damaged or chipped hob cutters be re-sharpened?

Minor chipping and normal wear can usually be corrected during re-sharpening. Each hob is evaluated before processing. Severely damaged tools are reported with technical recommendations. This ensures only serviceable hobs are reconditioned.

Q. What information is required to submit a hob for re-sharpening?

Basic details such as hob type, module, material, and application are helpful. Previous inspection reports can be shared if available. Physical samples are evaluated on receipt. This speeds up processing and accuracy.

Q. How do you ensure consistency across multiple re-sharpened hobs?

Controlled grinding processes and standardized inspection methods are used. Each hob is measured against defined parameters. This ensures repeatable quality. Batch consistency is maintained for production reliability.

Q. Does re-sharpening improve cutting surface finish?

Yes, sharp cutting edges improve chip formation. This results in smoother gear tooth surfaces. Burr formation is reduced. Overall gear finish quality improves.

Q. Is tool traceability maintained during re-sharpening?

Yes, tool identification and tracking are maintained throughout the process. Each hob is handled with care and proper labeling. This avoids mix-ups. Traceability supports quality assurance.

Our Other Services

Hob Cutter Resharpening

Shaving Cutter Resharpening

Master Gear Reprofiling

Hob Cutter Reprofiling

Broach Re-Sharpening