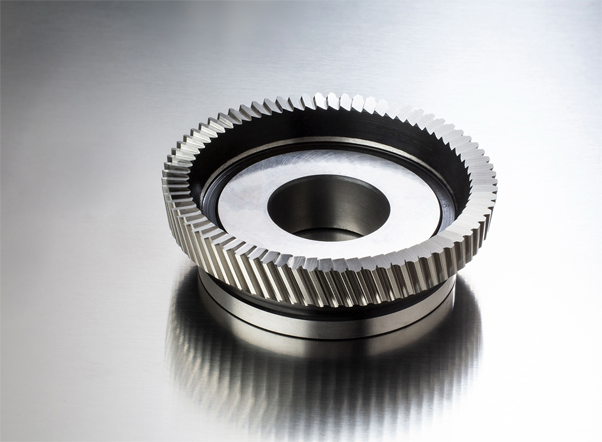

Helical Shaper Cutter

Technical Specification

| HELICAL SHAPER CUTTER | |

|---|---|

| Material | M2, M35, M42, ASP30, ASP52, S390 and Solid Carbide |

| Accuracy Class | ‘AA’ & ‘A’ as per DIN 1829 |

| Gear Type | Internal & External, Hub Type, Disc Type, Shank Type etc. |

Product FAQ’s

Q. Which industries commonly use helical shaper cutters?

Helical shaper cutters are widely used in automotive, gearbox, aerospace, robotics, and heavy machinery industries. They are essential where smooth gear operation is required. Super Tools Corporation supplies cutters suitable for both OEM and export markets.

Q. Can helical shaper cutters produce internal helical gears?

Yes, helical shaper cutters are ideal for producing internal helical gears where hobbing is not possible. They offer high profile accuracy even in confined spaces. Super Tools Corporation manufactures cutters suitable for internal and external gear shaping.

Q. Are helical shaper cutters suitable for CNC gear shapers?

Yes, they are fully compatible with modern CNC gear shaping machines. CNC operation ensures better synchronization and repeatability. Super Tools Corporation supplies cutters optimized for CNC and conventional gear shapers.

Q. Do helical shaper cutters support coated options?

Yes, advanced coatings such as TiN, TiAlN, and AlCrN are available to improve wear resistance. Coated cutters provide longer tool life and better surface finish. Super Tools Corporation offers coated solutions for demanding applications.

Q. Are custom helical shaper cutters available?

Super Tools Corporation offers custom helical shaper cutters for special gear profiles and applications. Customization ensures precise compatibility with unique gear designs. The company specializes in manufacturing custom-made helical shaper cutters for industrial needs.

Q. Are helical shaper cutters suitable for automotive gears?

Yes, they are widely used for automotive transmission and differential gears. Accuracy and smooth operation are critical in this sector. Super Tools Corporation supplies cutters meeting automotive quality demands.

Q. What is a helical shaper cutter used for?

A helical shaper cutter is used to machine precise helical gear teeth with smooth surface finish and accurate involute profiles. It is ideal for internal and external gears where high accuracy is required. Super Tools Corporation manufactures cutters designed for consistent industrial performance.

Q. Can helical shaper cutters be customized as per drawing?

Yes, helical shaper cutters can be customized based on gear drawings, specifications, and application needs. Customization ensures perfect compatibility with machine and gear design. Super Tools Corporation specializes in made-to-order helical shaper cutters.

Q. Do you supply helical shaper cutters for export markets?

Yes, helical shaper cutters are supplied worldwide with export-quality packing and documentation. Secure packaging ensures safe international delivery. Super Tools Corporation regularly exports cutters to global customers.

Q. Can helical shaper cutters be re-sharpened?

Helical shaper cutters can be re-sharpened multiple times while maintaining profile accuracy. Proper regrinding extends tool life and reduces tooling costs. Super Tools Corporation provides cutters suitable for repeated reconditioning.

Our Range of Shaper Cutters

Special Profile Shaper Cutter

Besides Standard Shaper Cutters, we also supply Special Profile Shaper Cutters...

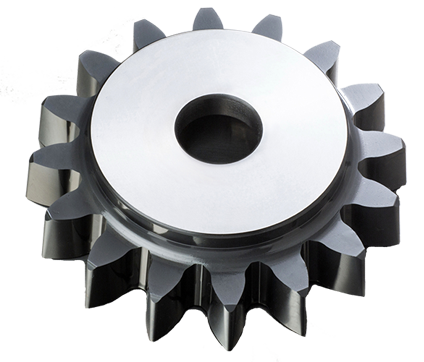

Disc Type Shaper Cutter

STC is a Manufacturer of Disc Type Gear Shaper Cutters designed to cut any gear, internal or external...

Shank Type Shaper Cutter

We are a Manufacturer of Shank Type Shaper Cutters, mainly used for cutting internal gears...

Hub Type Shaper Cutter

We are a Manufacturer and Exporter of Hub Type Shaper Cutters...

Helical Shaper Cutter

We are a Manufacturer of Helical Shaper Cutters, having their teeth inclined at a helix angle...

Timing Pulley Shaper Cutter

We are Manufacturer of Timing Pulley Shaper Cutter. These shaper cutters are manufactured...

Chain Sprocket Shaper Cutter

Besides Standard Shaper Cutters, we also provide customized Shaper Cutters as per specific customer...