Helical Spline Gauges

Product FAQ’s

Q. What are Helical Spline Gauges?

Helical spline gauges are precision inspection tools used to verify the dimensional accuracy of helical splines. They ensure correct tooth profile, lead, pitch, and alignment of splined components. These gauges help maintain interchangeability and functional performance. They are commonly used in quality control and production inspection.

Q. What types of Helical Spline Gauges are available?

Helical spline gauges are available as Go and No-Go plug gauges and segment gauges. They can be manufactured for internal and external helical splines. Variants include fixed limit gauges and adjustable gauge systems. Selection depends on spline standard, size, and inspection method.

Q. What load or inspection capacity do Helical Spline Gauges handle?

Helical spline gauges are designed for inspection rather than load bearing. They withstand repeated use without dimensional wear when properly hardened. High-grade tool steel ensures durability and stability. Consistent inspection accuracy is maintained over long service life.

Q. Where are Helical Spline Gauges commonly used?

They are widely used in automotive transmissions, gearboxes, and driveline components. Aerospace spline shafts and defense applications also rely on these gauges. Heavy equipment and industrial machinery manufacturers use them for quality control. They are essential in precision spline production environments.

Q. Can Helical Spline Gauges be customized as per drawing?

Yes, helical spline gauges can be fully customized as per customer drawings or spline data. Parameters such as module, pressure angle, lead angle, and tolerance can be tailored. Both standard and non-standard spline profiles are supported. Customization ensures exact match with production components.

Q. Do Helical Spline Gauges comply with export standards?

Yes, helical spline gauges are manufactured to meet international export standards. Each gauge is inspected and supplied with dimensional and material certification. Export-grade packing ensures safe global transportation. Compliance supports acceptance in global OEM supply chains.

Q. How are Helical Spline Gauges installed and used?

Installation is simple and requires proper alignment with the spline component. The gauge is gently engaged to check fit and profile accuracy. No complex setup or machinery is required. Operator training ensures consistent inspection result

Q. Are Helical Spline Gauges environmentally sustainable?

Long service life reduces frequent replacement and material waste. Precision inspection minimizes scrap and rework in production. Durable materials ensure efficient resource utilization. This contributes to sustainable manufacturing practices.

Q. How do Helical Spline Gauges improve manufacturing efficiency?

They provide quick and reliable inspection without complex measurement equipment. Early detection of spline errors reduces rework and rejection. Consistent gauging improves process control. This leads to higher production efficiency.

Q. What surface finish is required for Helical Spline Gauges?

Helical spline gauges are finished to a fine ground or lapped surface. Smooth finish reduces friction during inspection. It prevents component or gauge damage. High finish ensures consistent results.

Our Range of Gauges

Spline Gauges

Spline Plug Gauges can be manufactured in following profiles:

Spline Plug Gauges can be manufactured in following profiles:

Involute Spline

Straight Spline

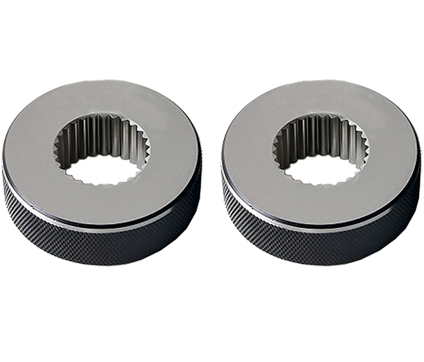

Spline Ring Gauges

Go Ring Gauges

Master or set Ring Gauges