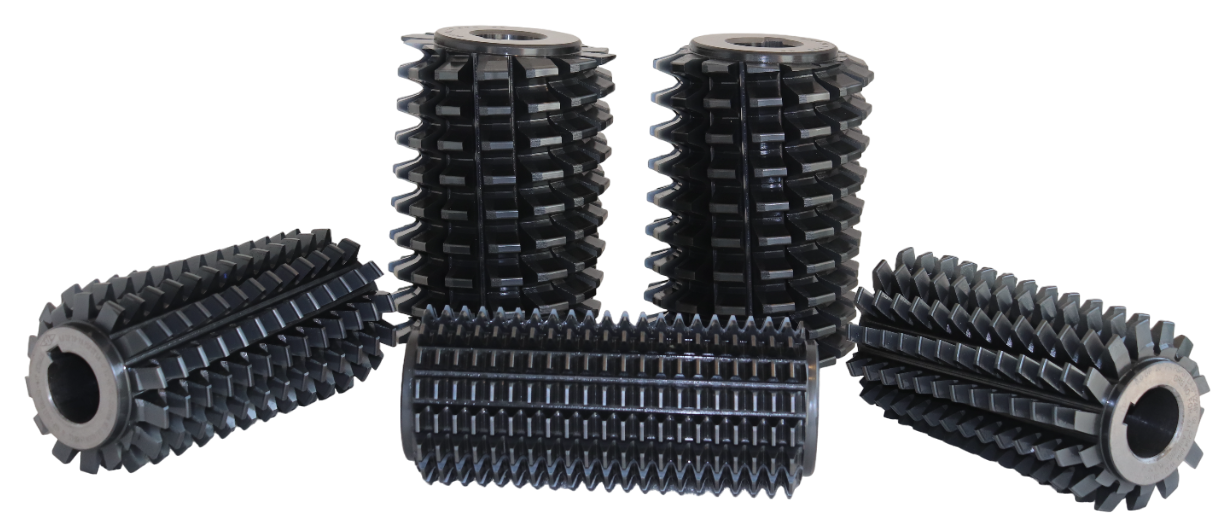

Gear Hobs

STC is a Manufacturer and Exporter of all types of Gear Cutting Tools in HSS and Carbide Materials made with maximum accuracy and proper finishing. These Gear Hobs can be manufactured in Bore and Shank Types. Besides Gear Hobs, we also supply custom gear Hobs as per customer drawings.

These are used to generate gear tooth profiles in any material. Gear Hob Cutters are available in all kinds of PVD coatings as per our customers’ requirements. The Hobs are produced in bore or shank type in single or multi-threads.

At STC, we focus on precision, performance, and customization, ensuring our Gear Hobs meet international standards and exceed customer expectations in both quality and durability. With flexible production capabilities and fast turnaround, STC supports both small batch and bulk requirements. Our tools are trusted by gear manufacturers worldwide for reliability, precision, and value.

Note: Special features like Topping, Semi Topping, Protuberance, Pre-Grinding, Pre-Shaving etc. can also be provided as per Customer’s requirement.

Technical Specification

| GEAR HOB | |

|---|---|

| Materials | S390/ ASP2052/ ASP2030/ S290/ ASP2060/ S590/ M35/ M2 |

| Types | Bore & Shank |

| Maximum Diameter | 300 mm |

| Maximum Length | 350 mm |

| Module Range | 0.2 to 32 Module |

| Accuracy class | Up to AAA as per DIN3968 |

| PVD Coatings | TiN, Alcrona Pro & Altensa |

| Standards | DIN 3972, DIN 867, DIN 8000, IS8731, ISO 53, GOST 6637, GOST 9324, GOST 13755 |

Product FAQ’s

Q. What are the key technical specifications of gear hobs?

Key specifications include module, DP, pressure angle, helix angle, and number of starts. Outside diameter, bore size, and cutting length define tool capacity. Accuracy classes follow DIN or ISO standards. Material grade and coating determine tool life and performance.

Q. How much load can a gear hob handle?

Load capacity depends on hob material, module size, coating, and machine rigidity. Higher-accuracy hobs with proper coating can handle greater cutting forces and resist wear under continuous production. Multi-start hobs reduce cycle time but increase cutting forces. Proper parameter selection ensures safe and stable operation.

Q. Can gear hobs be customized?

Yes, gear hobs can be customized as per customer drawings and gear specifications. Customization includes profile correction, coatings, and special dimensions. Special hobs are made for non-standard gears. This ensures exact fit for specific applications.

Q. Do gear hobs meet international export standards?

Yes, STC gear hobs are manufactured as per DIN, ISO, AGMA, and customer-specific standards. Export tools are inspected for accuracy and material quality. Heat treatment and testing follow global norms. Compliance ensures acceptance in international markets.

Q. What is the load capacity of a gear hob?

• The load capacity of a gear hob depends on hob material, module size, number of starts, and face width.

• HSS and coated hobs handle moderate to high cutting loads, while carbide hobs support heavier loads.

• Proper cutting speed, feed rate, machine rigidity, and lubrication maximize safe load capacity.

Q. What drawings are required to manufacture a gear hob?

Gear drawings with module, pressure angle, and tooth details are required. Workpiece material and hardness must be specified. Machine details help optimize design. Clear drawings ensure accurate manufacturing.

Q. How are gear hobs installed on machines?

Gear hobs are installed by mounting them securely on the machine arbor or hob spindle with correct alignment and clamping. Proper concentricity and axial positioning are set to match the gear parameters. Cutting speed, feed, and depth are then adjusted as per the hob and workpiece material.

Q. What is the role of helix angle in gear hobs?

Helix angle defines the gear tooth inclination. It affects load distribution and noise levels. Gear hobs are designed to match helix requirements. Incorrect angles cause gear mismatch.

Q. Why is Super Tools Corporation recognized as a Top HSS Hob Cutter Manufacturer in India?

Super Tools Corporation is recognized as a Top HSS Hob Cutter Manufacturer in India due to its precision manufacturing and consistent quality. The company uses premium HSS grades and advanced production technology. Strict quality control ensures reliable performance in high-volume gear cutting. Global OEMs trust Super Tools Corporation for accuracy and durability.

Q. How does the gear hobbing process work?

Gear hobbing is a continuous cutting process where the hob and workpiece rotate in synchronization. The hob progressively forms gear teeth along the blank. This method allows high productivity and precision. It is suitable for both external and internal gears.

Our Range of HSS Hob Cutters

Gear Hobs

STC is a Manufacturer of Gear Hobs made with maximum accuracy and proper finishing.

Spline Hobs

We are a Manufacturer of Spline Hobs, in Standard and specific customer requirements.

Accuracy class:

Sprocket Hobs

We can also manufacture Chain Sprocket Hobs as per customer requirements or drawings.

Accuracy Class:

Timing Pulley Hobs

We are a Manufacturer of Timing Pulley Hobs in high quality as per ANSI, BS, IS, or any other...

Accuracy :

Worm Hobs

Serration Hobs

We are a Manufacturer and Exporter of Serration Hobs, which are used for generating gears of maximum...

Special Profile Hobs

Besides Standard Gear Hobs, we also Manufacture Special Profile for various components like missing...