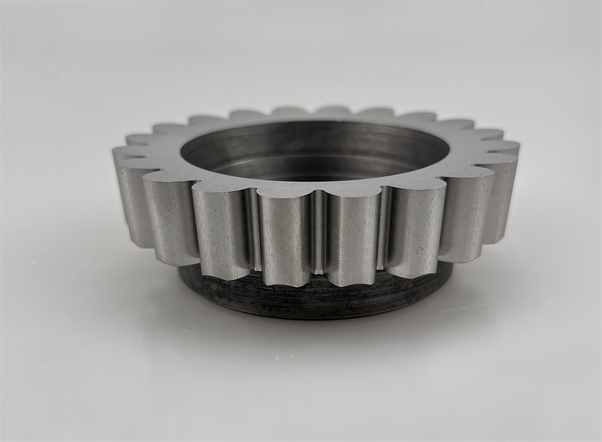

Chain Sprocket Shaper Cutter

Our Chain Sprocket Shaper Cutters are manufactured from high-quality tool steel for superior wear resistance and long service life. Precision tooth profiles ensure smooth cutting action and consistent sprocket geometry. These cutters are widely used in chain sprocket manufacturing, automotive components, and industrial transmission systems. Advanced manufacturing processes ensure high dimensional accuracy and repeatability. Export-grade packaging is provided to ensure safe delivery to global customers.

Product FAQ’s

Q. What is a Chain Sprocket Shaper Cutter?

A chain sprocket shaper cutter is a precision cutting tool used to machine accurate tooth profiles on chain sprockets. It is designed with exact tooth geometry based on chain standards. The cutter delivers consistent tooth spacing and smooth surface finish. It is compatible with standard gear shaping machines used in industrial production.

Q. What types of Chain Sprocket Shaper Cutters are available?

Chain sprocket shaper cutters are available for simplex, duplex, and triplex chain sprockets. They are manufactured for ISO, ANSI, DIN, and BS chain standards. Different bore sizes and shank types are offered for machine compatibility. Custom profiles can also be produced for special chain designs.

Q. What materials are used to manufacture Chain Sprocket Shaper Cutters?

Super Tools Corporation manufactures these cutters using high-speed steel grades such as M2 and M35. Premium materials ensure wear resistance and dimensional stability. Controlled heat treatment improves strength and durability. This supports repeated regrinding and extended tool life.

Q. What load capacity and performance can be expected?

Chain sprocket shaper cutters are designed to handle continuous industrial cutting loads. Stable cutting action minimizes vibration during machining. Accurate tooth generation improves load distribution across sprocket teeth. This results in longer sprocket service life and reliable operation.

Q. Are Chain Sprocket Shaper Cutters compatible with standard shaping machines?

Super Tools Corporation manufactures cutters compatible with conventional gear shaping machines. Mounting dimensions follow industry-standard configurations. This ensures easy integration into existing production setups. Installation does not require major machine modifications.

Q. How are Chain Sprocket Shaper Cutters installed and maintained?

Installation involves correct alignment and secure clamping on the shaping machine. Regular inspection maintains cutting accuracy. Cutters can be reground multiple times to extend life. Proper lubrication and storage prevent wear and corrosion.

Q. Can Chain Sprocket Shaper Cutters be customized as per drawings?

Super Tools Corporation manufactures chain sprocket shaper cutters as per customer drawings and specifications. Custom chain pitch, tooth form, and bore sizes are supported. Special tolerances and coatings can be provided. Customization ensures precise compatibility with unique sprocket designs.

Q. Do Chain Sprocket Shaper Cutters meet export standards and compliance?

Super Tools Corporation produces cutters in compliance with ISO and international quality standards. Dimensional accuracy and material traceability are strictly controlled. Export-grade packaging ensures corrosion protection. Compliance supports acceptance in global markets.

Q. Are Chain Sprocket Shaper Cutters re-sharpenable?

Yes, these cutters can be re-sharpened multiple times. Proper regrinding restores cutting edges while maintaining profile accuracy. This significantly extends tool life. Re-sharpening helps reduce tooling cost.

Q. How are Chain Sprocket Shaper Cutters environmentally sustainable?

Long tool life reduces frequent replacements and material waste. Regrinding capability supports sustainable manufacturing practices. Efficient cutting lowers power consumption during machining. This contributes to reduced environmental impact.

Our Range of Shaper Cutters

Special Profile Shaper Cutter

Besides Standard Shaper Cutters, we also supply Special Profile Shaper Cutters...

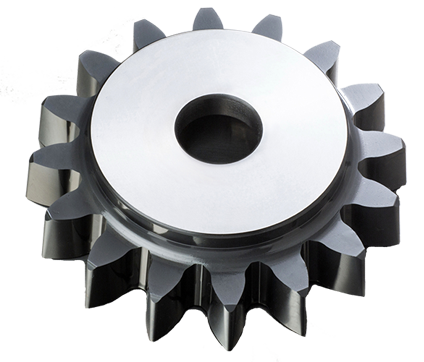

Disc Type Shaper Cutter

STC is a Manufacturer of Disc Type Gear Shaper Cutters designed to cut any gear, internal or external...

Shank Type Shaper Cutter

We are a Manufacturer of Shank Type Shaper Cutters, mainly used for cutting internal gears...

Hub Type Shaper Cutter

We are a Manufacturer and Exporter of Hub Type Shaper Cutters...

Helical Shaper Cutter

We are a Manufacturer of Helical Shaper Cutters, having their teeth inclined at a helix angle...

Timing Pulley Shaper Cutter

We are Manufacturer of Timing Pulley Shaper Cutter. These shaper cutters are manufactured...

Chain Sprocket Shaper Cutter

Besides Standard Shaper Cutters, we also provide customized Shaper Cutters as per specific customer...