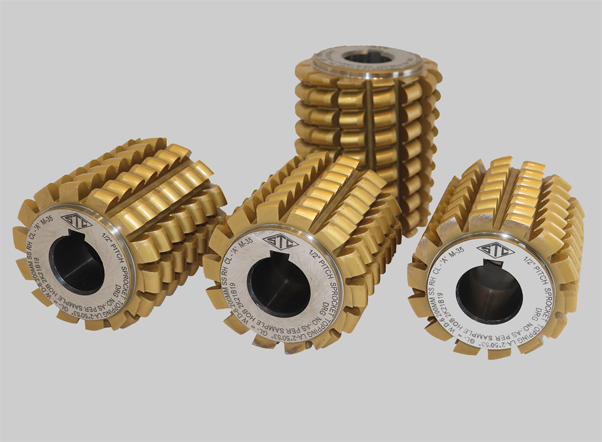

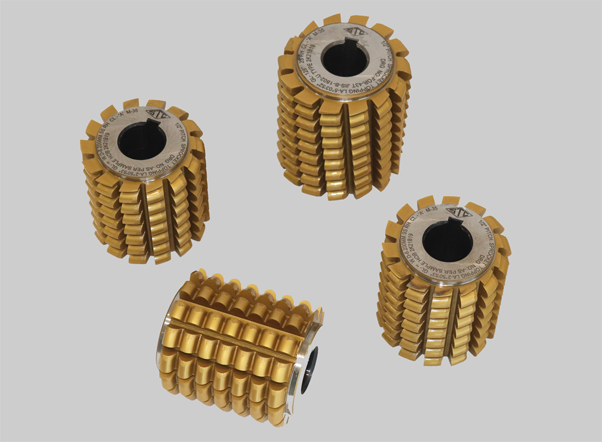

Sprocket Hobs

Our Chain Sprocket Hobs has a smooth finish, precise design, and high strength. Chain Sprocket Hobs are specially designed in multi-threads for high productivity. STC Chain Sprocket Hobs are manufactured using premium-grade HSS and imported raw materials, ensuring reliable performance in demanding production environments.

To further improve performance and durability, Chain Sprocket Hobs are available in all types of PVD coatings such as TiN, TiAlN, AlTiN, and other advanced coatings as per customer requirements. These Hobs are widely used in automotive, industrial machinery, and transmission component manufacturing. Each hob is precision-ground and quality-checked to meet international manufacturing standards for accuracy and repeatability.

Technical Specification

| CHAIN SPROCKET HOBS | |

|---|---|

| Materials | S390/ ASP2052/ ASP2030/ S290/ ASP2060/ M35/ M42/ M2 |

| Standards | ANSI, ASA, IS, DIN, JIS-B |

| Types | Topping & Non-topping |

| Threads | Single or multi-threads for high-speed cutting. |

| Sprocket Pitch Range | 3.5 inch or 90mm |

Product FAQ’s

Q. What industries use HSS chain sprocket hobs?

These hobs are widely used in automotive, agricultural machinery, industrial transmission, and conveyor system manufacturing. They are essential for producing sprockets used in power transmission systems. Heavy engineering and material handling industries also rely on them. OEMs and Tier-1 suppliers are major users.

Q. What technical specifications define a chain sprocket hob?

Key specifications include module or pitch, pressure angle, number of starts, outside diameter, and bore size. Accuracy class and lead tolerance define cutting precision. Hob length and gash geometry affect chip evacuation. Specifications are selected based on sprocket size and production speed.

Q. What load capacity can HSS chain sprocket hobs handle?

HSS Chain Sprocket hobs can handle medium to high cutting loads depending on material grade and coating. They are suitable for cutting carbon steel, alloy steel, and case-hardening steel. Proper machine rigidity ensures stable cutting under load. Load capacity improves with optimized cutting parameters.

Q. Do your chain sprocket hobs meet export standards?

Yes, Super Tools Corporation supplies export-quality chain sprocket hobs. Tools comply with ANSI, ASA, IS, DIN, and JIS-B standards. Inspection reports and material certificates are provided. Export packaging ensures safe global delivery.

Q. Why choose Super Tools Corporation for HSS chain sprocket hobs?

Super Tools Corporation offers precision manufacturing, customization, and export-quality standards. Our hobs deliver reliable performance and long tool life. We support global OEMs and industrial buyers. This makes us a trusted chain sprocket hob manufacturer.

Q. What manufacturing tolerances are applied to chain sprocket hobs?

Super Tools Corporation applies tight dimensional and geometric tolerances during hob manufacturing. Lead, pitch, and profile deviations are strictly controlled. This ensures repeatable and accurate sprocket production.

Q. Can HSS chain sprocket hobs be re-sharpened multiple times?

Yes, they can be re-sharpened several times without profile loss. Proper grinding maintains tooth geometry. This extends overall tool life significantly. It also reduces tooling cost per component.

Q. Can HSS chain sprocket hobs be re-sharpened?

Yes, HSS chain sprocket hobs can be re-sharpened multiple times without affecting tooth accuracy.

Re-sharpening restores cutting edges and significantly extends tool life.

Proper grinding methods ensure consistent performance and reduced tooling cost.

Q. How does tooth profile accuracy affect sprocket performance?

Accurate tooth profiles ensure smooth chain engagement. This reduces noise and vibration during operation. Proper profiles improve load distribution across teeth. Overall sprocket life increases significantly.

Q. How does hob design influence chip evacuation?

Hob design directly affects chip evacuation through flute geometry, helix angle, and rake design.

Optimized flutes allow smooth chip flow, reducing clogging and heat generation.

Efficient chip evacuation improves surface finish and extends hob tool life.

Our Range of HSS Hob Cutters

Gear Hobs

STC is a Manufacturer of Gear Hobs made with maximum accuracy and proper finishing.

Spline Hobs

We are a Manufacturer of Spline Hobs, in Standard and specific customer requirements.

Accuracy class:

Sprocket Hobs

We can also manufacture Chain Sprocket Hobs as per customer requirements or drawings.

Accuracy Class:

Timing Pulley Hobs

We are a Manufacturer of Timing Pulley Hobs in high quality as per ANSI, BS, IS, or any other...

Accuracy :

Worm Hobs

Serration Hobs

We are a Manufacturer and Exporter of Serration Hobs, which are used for generating gears of maximum...

Special Profile Hobs

Besides Standard Gear Hobs, we also Manufacture Special Profile for various components like missing...