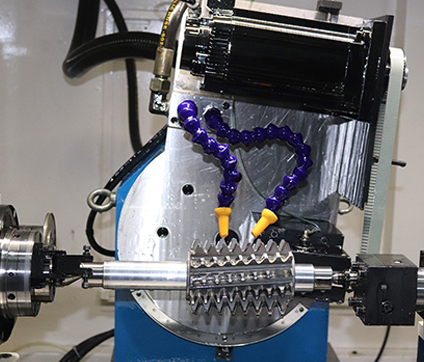

Hob Cutter Re-Profiling

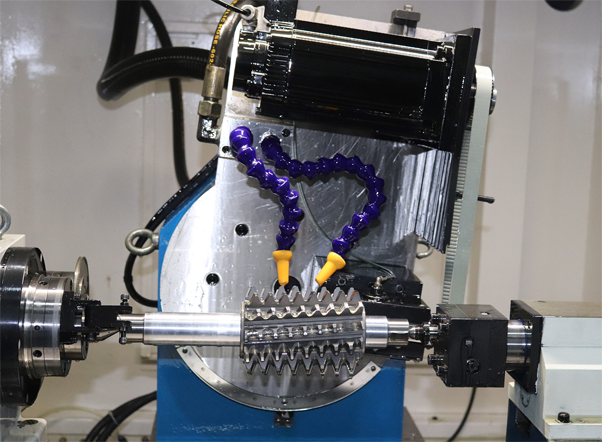

Precision Hob Cutter Re-Profiling for Extended Tool Life & Accurate Gear Cutting

Super Tools Corporation provides professional Hob Cutter Re-Profiling Services to restore worn gear hobs to their original tooth geometry, profile accuracy, and cutting performance. Our re-profiling solutions help gear manufacturers reduce tooling costs, maintain consistent gear quality, and extend hob service life without compromising precision.

What is Hob Cutter Re-Profiling?

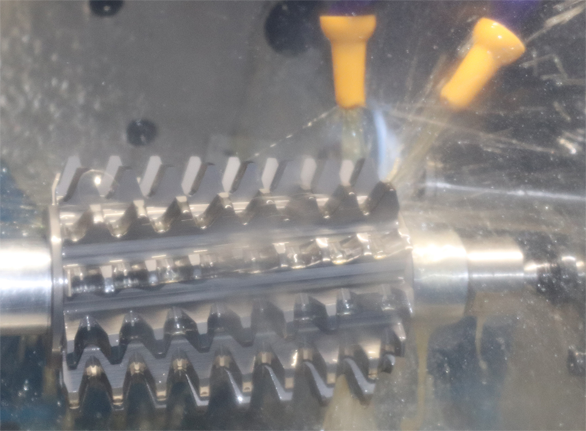

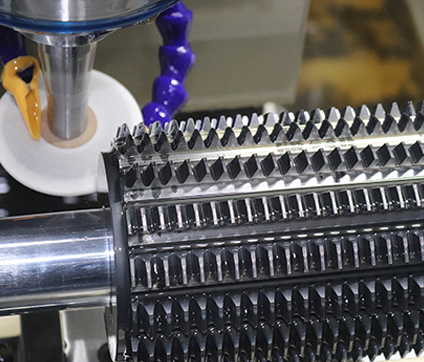

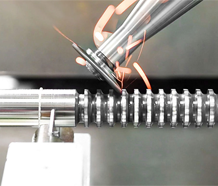

Hob cutter re-profiling is a specialized precision grinding process that restores the original tooth profile, lead, and geometry of worn or damaged hobs. Unlike standard re-sharpening, re-profiling corrects profile deviations, tooth form errors, and wear patterns that affect gear accuracy and surface finish.

This service is ideal for hobs that have experienced profile distortion, uneven wear, or performance loss during high-volume gear production.

Service capabilities include:

Each hob is carefully evaluated before processing to ensure suitability for re-profiling.

Materials & Hob Types We Re-Profile

We provide hob cutter re-profiling services for a wide range of materials and designs:

- Gear Hobs

- Spline Hobs

- Sprocket Hobs

- Timing Pulley Hobs

- Worm Gear Hobs

- Special Profile Hobs

Custom and non-standard profiles are accepted based on technical feasibility.

Why Choose Hob Cutter Re-Profiling?

Restore Gear Accuracy

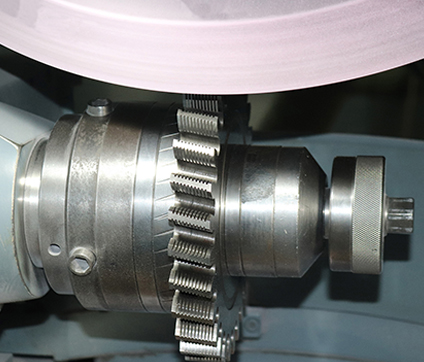

Re-profiling restores the correct tooth form, ensuring consistent gear geometry, improved load distribution, and reduced noise in finished gears.

Extend Tool Life

By correcting profile wear, hobs can be reused for multiple production cycles, significantly reducing tooling replacement costs.

Improve Cutting Performance

Accurate re-profiled hobs provide stable cutting action, lower vibration, and better surface finish.

Cost-Effective Alternative

Re-profiling is a practical and economical alternative to purchasing new hobs, especially for large or custom-profile tools.

Why Choose Super Tools for Hob Cutter Re-Profiling?

Decades of experience in gear cutting tools

Product FAQ’s

Q. What is Hob Cutter Re-Profiling?

Hob cutter re-profiling is a precision grinding process used to restore the original tooth profile and geometry of worn hobs. It corrects profile distortion, flank wear, and lead errors. This ensures accurate gear generation and stable cutting performance. Re-profiling is more advanced than standard re-sharpening.

Q. When should a hob cutter be re-profiled?

A hob should be re-profiled when gears show profile errors, noise, or uneven wear. It is also required when standard re-sharpening no longer delivers accurate results. Visible tooth distortion or loss of profile accuracy indicates the need for re-profiling. Early correction prevents scrap and rework.

Q. What types of hob cutters can be re-profiled?

Gear hobs, spline hobs, sprocket hobs, timing pulley hobs, worm hobs, and special profile hobs can be re-profiled. Both single-start and multi-start hobs are supported. Custom and non-standard profiles are accepted. Feasibility depends on remaining material and wear condition.

Q. Which materials are suitable for hob cutter re-profiling?

Hob cutter re-profiling is suitable for HSS, HSS-Co, PM-HSS, and solid carbide hobs. Material condition is evaluated before processing. Proper grinding parameters are selected to maintain tool integrity. This ensures safe and precise profile restoration.

Q. Can hobs be re-profiled as per original drawing or master hob?

Yes, hobs can be re-profiled as per original manufacturing drawings or master hob references. Profile, lead, and pitch accuracy are carefully restored. This ensures compatibility with existing gear designs. Precision inspection is performed to validate results.

Q. What industries use hob cutter re-profiling services?

Hob cutter re-profiling is widely used in automotive, EV transmission, industrial gearbox, agriculture machinery, construction equipment, and heavy engineering sectors. Any industry requiring precision gears benefits from re-profiling. It helps maintain production quality and consistency. The service supports both OEMs and tier suppliers.

Q. What quality checks are performed after re-profiling?

After re-profiling, hobs undergo profile inspection, dimensional verification, and surface condition checks. Lead and tooth form accuracy are verified using precision instruments. Final validation ensures readiness for production use. This guarantees reliable gear cutting performance.

Q. Who provides professional hob cutter re-profiling services?

Super Tools Corporation provides professional hob cutter re-profiling services using advanced CNC grinding and inspection systems. The company offers accurate profile restoration and consistent quality. Technical support is available for tool evaluation and optimization. Services are trusted by gear manufacturers in India.

Our Other Services

Hob Cutter Resharpening

Shaving Cutter Resharpening

Master Gear Reprofiling

Hob Cutter Reprofiling

Broach Re-Sharpening