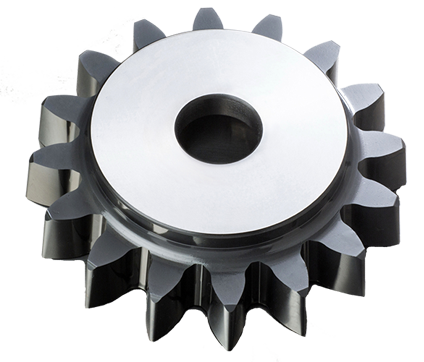

Timing Pulley Shaper cutter

If you have any specific size, drawing, or technical requirement, you can share complete details with us, and we will deliver a high-quality, precision-engineered solution within a short lead time, ensuring reliable performance and cost efficiency.

Technical Specification

| TIMING PULLEY SHAPER CUTTER | |

|---|---|

| Material | M2, M35, M42, ASP30, ASP52, S390 and Solid Carbide |

| Accuracy | ‘AA’ & ‘A’ as per DIN 1829 |

| Coating | TiN coating, TiAIN Coating or uncoated |

| Gear Type | Internal & External, Hub Type, Disc Type, Shank Type etc. |

Product FAQ’s

Q. What is a Timing Pulley Shaper Cutter?

A Timing Pulley Shaper Cutter is a precision cutting tool used to machine accurate tooth profiles on timing pulleys. It ensures correct pitch, profile geometry, and smooth belt engagement. Super Tools Corporation manufactures these cutters for high accuracy and consistent performance. They are widely used in synchronous belt drive applications.

Q. What materials are used in Timing Pulley Shaper Cutters?

Super Tools Corporation manufactures Timing Pulley Shaper Cutters using high-grade HSS materials such as M2, M35, and M42. Material selection depends on cutting conditions and required tool life. Premium steels ensure wear resistance and dimensional stability. Custom material grades can also be provided on request.

Q. What materials are timing pulley shaper cutters made from?

Timing pulley shaper cutters are made from high-performance tool steels such as M2, M35, and M42 for strength and heat resistance. Powder metallurgy steels like ASP30 and ASP52 are used for higher wear resistance and longer tool life.

Q. Why do timing pulleys require shaper cutters?

Timing pulleys require shaper cutters to accurately produce precise tooth profiles and correct pitch geometry. Shaper cutters ensure consistent engagement with belts, smooth power transmission, and reduced noise and wear.

Q. Can timing pulley shaper cutters be customized?

Yes, Super Tools Corporation manufactures timing pulley shaper cutters that can be fully customized as per specific pulley profiles, tooth forms, and pitch requirements. Customization ensures accurate machining and optimal belt engagement. It also improves performance for special and OEM applications.

Q. Are coated timing pulley shaper cutters available?

Yes, optional coatings such as TiN, TiAlN, or AlCrN can be applied to improve wear resistance. Coatings enhance tool life in high-volume production. Super Tools Corporation offers coated cutters on customer request.

Q. Are timing pulley shaper cutters suitable for export OEM supply?

Yes, these cutters are widely supplied to OEMs for domestic and export markets. Quality consistency is essential for OEM acceptance. Super Tools Corporation is a trusted OEM supplier of timing pulley shaper cutters.

Q. Can timing pulley shaper cutters handle complex pulley profiles?

Yes, shaper cutters are ideal for complex and special timing pulley profiles. They offer flexibility where standard tools may not work. Super Tools Corporation specializes in complex profile cutter manufacturing.

Q. Are timing pulley shaper cutters suitable for heavy-duty applications?

Yes, they can be designed for heavy-duty and high-torque pulley applications. Strong tooth profiles help distribute loads evenly. Super Tools Corporation customizes cutters for demanding industrial use.

Q. Can timing pulley shaper cutters be used for steel pulleys?

Yes, timing pulley shaper cutters are suitable for carbon steel and alloy steel pulleys. Correct heat treatment and cutting parameters are required for optimal results. Super Tools Corporation manufactures cutters designed for stable cutting in steel materials.

Our Range of Shaper Cutters

Special Profile Shaper Cutter

Besides Standard Shaper Cutters, we also supply Special Profile Shaper Cutters...

Disc Type Shaper Cutter

STC is a Manufacturer of Disc Type Gear Shaper Cutters designed to cut any gear, internal or external...

Shank Type Shaper Cutter

We are a Manufacturer of Shank Type Shaper Cutters, mainly used for cutting internal gears...

Hub Type Shaper Cutter

We are a Manufacturer and Exporter of Hub Type Shaper Cutters...

Helical Shaper Cutter

We are a Manufacturer of Helical Shaper Cutters, having their teeth inclined at a helix angle...

Timing Pulley Shaper Cutter

We are Manufacturer of Timing Pulley Shaper Cutter. These shaper cutters are manufactured...

Chain Sprocket Shaper Cutter

Besides Standard Shaper Cutters, we also provide customized Shaper Cutters as per specific customer...