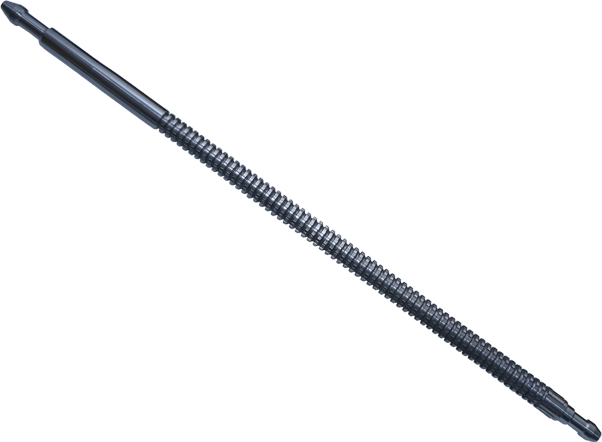

Straight Spline Broaches

Straight Spline Broaches that we produce are widely known for their durability and quality. These Straight Spline Broaches are engineered for high accuracy and consistent spline geometry across production batches. Precision machining and controlled heat treatment enhance strength, wear resistance, and tool life. They are suitable for automotive, gearbox, transmission, and heavy engineering applications. Both standard and custom spline profiles can be manufactured as per customer drawings. Advanced grinding ensures smooth cutting action and reduced surface finish errors. The broaches support stable performance in high-volume production environments. Strict quality checks are followed to comply with DIN and JIS requirements. Export-grade packaging ensures safe worldwide delivery. Technical support is available for tool selection, application, and maintenance guidance.

Technical Specification

| STRAIGHT SPLINE BROACHES | |

|---|---|

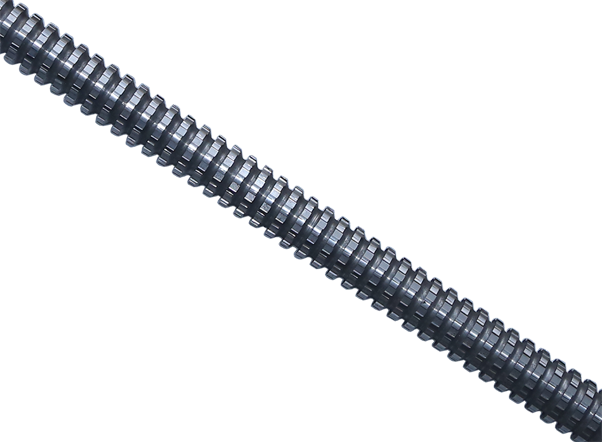

| Material | HSS M2, M35, M42, ASP 2030, ASP 2052, ASP 2060. |

| Coating | TiN, TiAIN or as required |

| Standard | GB, DIN, BS, & ANSI |

| Max. Od | 280mm |

| Max. Length | Up to 2000mm |

Product FAQ’s

Q. What materials are used for manufacturing straight spline broaches?

Straight spline broaches are typically manufactured from high-speed steel (HSS) for toughness and wear resistance in standard applications, while powder-metallurgy HSS is used for improved tool life and consistency. Solid carbide or carbide-tipped materials are selected for high-volume production and hard materials, and advanced surface coatings like TiN or TiAlN are applied to enhance wear resistance and cutting performance.

Q. Can Super Tools manufacture custom straight spline broaches?

Yes. Super Tools specializes in manufacturing custom straight spline broaches precisely as per customer drawings, samples, or detailed spline data sheets, ensuring accurate tooth geometry and fit. Each broach is engineered to meet specific application requirements, delivering consistent performance, high accuracy, and long tool life in production environments.

Q. How is tooth rise calculated in a straight spline broach?

Tooth rise in a straight spline broach is calculated by dividing the total material to be removed by the number of cutting teeth, ensuring a gradual increase in tooth height along the broach length.

Q. What factors affect cutting forces in straight spline broaching?

Cutting forces in straight spline broaching are influenced by workpiece material hardness and machinability, tooth rise per tooth, and total number of cutting teeth. Additional factors include broach geometry, cutting speed, lubrication quality, and machine rigidity, all of which affect load, surface finish, and tool life.

Q. Can straight spline broaches be re-sharpened?

Yes, straight spline broaches can be re-sharpened multiple times using precision grinding while preserving the original spline profile and tooth geometry. Proper re-sharpening restores cutting performance, maintains dimensional accuracy, and helps extend tool life.

Q. Are straight spline broaches suitable for internal splines?

Yes, straight spline broaches are specifically designed for machining internal spline profiles with high accuracy and repeatability. They produce consistent tooth form and surface finish, making them ideal for automotive, industrial, and precision mechanical components.

Q. What technical specifications define a straight spline broach?

Key specifications include spline count, module or DP, pressure angle, tooth width, and broach length. Load capacity is determined by tooth geometry and broach material. Tolerances are maintained as per international spline standards. Specifications are optimized to balance strength and cutting efficiency.

Q. How are straight spline broaches installed?

Installation depends on whether the broach is push-type or pull-type. Accurate alignment with guide bushings is essential for spline quality. Secure mounting prevents uneven cutting and tool damage. Installation instructions ensure safe and efficient operation.

Q. What tolerances can be achieved with straight spline broaches?

Straight spline broaches achieve tight tolerances depending on tool design and machine condition. Consistent spline width and pitch are maintained throughout production. Precision tooling minimizes variation between components. This ensures proper fit and long service life.

Our Range of Broaches

Involute Spline Broaches

STC manufactures Involute Spline Broaches; besides manufacturing Spline Broaches...

Serration Broaches

We are a Manufacturer of Serration Broaches that is designed to be used individually or as a coupling...

Straight Spline Broaches

We are a Manufacturer of Straight Spline Broaches per world standards like DIN and JIS...

Round Broaches

We are a Manufacturer of a large selection of Round Broaches for use in various applications...

Keyway Broaches

We are a Manufacturer of Keyway Broaches, available in Inch and Metric sizes...

Square Broaches

We are a Manufacturer of Square Broaches, also known as “square hole broaches...

Helical Broaches

STC is Manufacturer of Helical Broaches to get the maximum helix angle accuracy ...