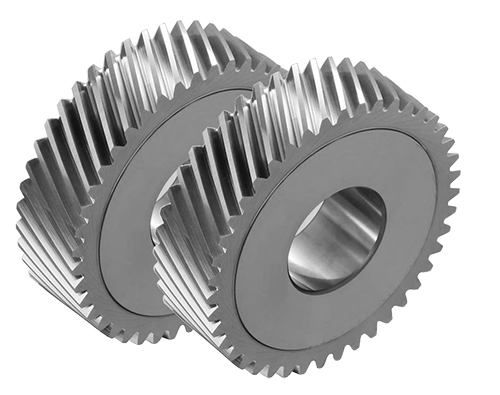

Master Gear

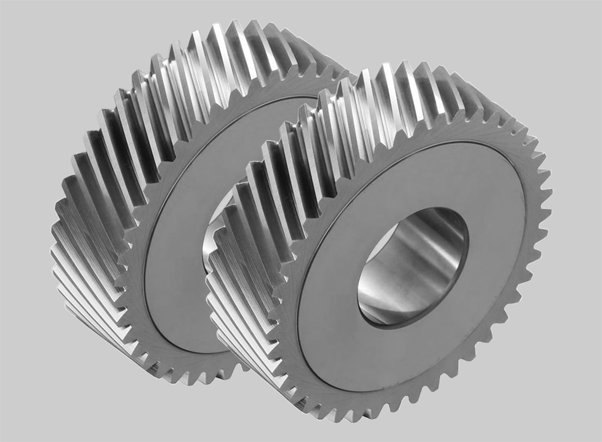

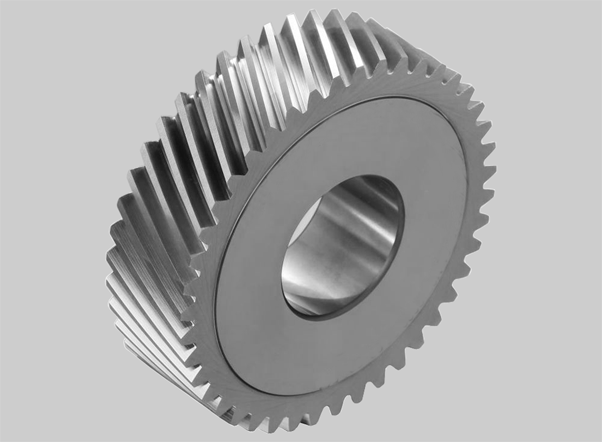

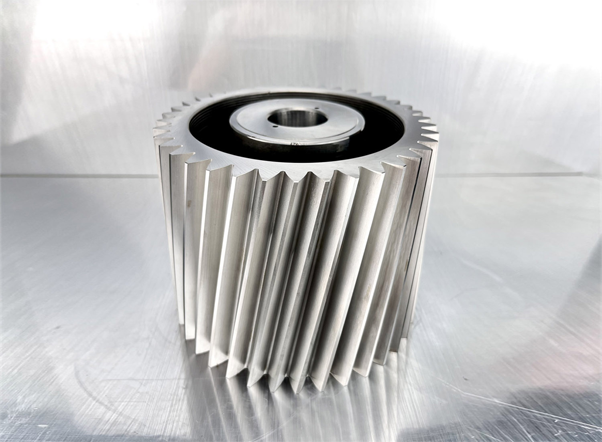

STC Manufacture Master Gears as per customer requirement for flank and profile checking applications. We provide different types of Master Gears, including cylindrical gears and pinions. These Master Gears are widely used in double and single flank gear roll inspection systems, honing machines, and advanced gear measuring systems as reference test gears. Our Master Gears are produced to the highest accuracy standards to determine the precision of work gears and to set masters for adjusting checking equipment.

In addition, STC Master Gears ensure repeatable and reliable inspection results in production and quality control environments. They are manufactured with strict control over tooth geometry, profile, lead, and pitch accuracy. High-grade materials and controlled heat treatment ensure long service life and dimensional stability. Custom accuracy classes and specifications are available to match international gear inspection standards. These precision Master Gears help improve gear quality, reduce inspection errors, and enhance overall manufacturing efficiency.

Technical Specification

| MASTER GEAR | |

|---|---|

| Module Range | 0.20 to 8 Module. |

| PCD | 20 mm to 220 mm |

| Material | M2/M35 |

| Thickness | Upto 150 mm |

| Helix Angle | Upto 45 Degree |

| Accuracy Class | Accuracy class IV as per DIN 3962 |

| Type | Spur & Helical |

Product FAQ’s

Q. What types of Master Gears does STC manufacture?

STC manufactures different types of Master Gears including cylindrical master gears and master pinions. These are produced for various gear modules and profiles. Designs are optimized for inspection accuracy rather than power transmission. Each type suits specific gear testing requirements.

Q. Can STC manufacture Master Gears as per customer requirements?

Yes, STC manufactures Master Gears strictly as per customer drawings and inspection needs. Customization includes tooth profile, flank geometry, module, and accuracy class. Gears are tailored to match specific checking equipment. This ensures perfect compatibility with customer systems.

Q. What quality standards are followed in STC Master Gear manufacturing?

STC Master Gears are produced using high-grade materials and controlled manufacturing processes. Strict inspection ensures dimensional and profile accuracy. Each gear meets demanding industrial quality expectations. This guarantees long-term reliability in inspection applications.

Q. What pitch circle diameter (PCD) range is available for Master Gears?

Master Gears are produced with PCD ranging from 20 mm to 220 mm. This allows use in small as well as large gear inspection setups. The wide PCD range supports multiple machine configurations. It ensures accurate flank and profile checking

Q. Which materials are used for manufacturing Master Gears?

Master Gears are manufactured using high-quality HSS M2. These materials provide excellent wear resistance and dimensional stability. They maintain accuracy over long inspection cycles. This ensures consistent and reliable measurement performance.

Q. Are these Master Gears suitable for single and double flank inspection systems?

Yes, these Master Gears are suitable for both single flank and double flank gear roll inspection systems. They are also used in honing machines and gear measuring systems. The design supports their role as test gears. This ensures accurate evaluation of work gears.

Q. What quality standards are followed in Master Gear manufacturing?

STC Master Gears are produced using high-grade materials and controlled manufacturing processes. Strict inspection ensures dimensional and profile accuracy. Each gear meets demanding industrial quality expectations. This guarantees long-term reliability in inspection applications.

Q. How should Master Gears be installed and maintained?

Master Gears should be installed with correct alignment on calibrated equipment. Regular cleaning and rust prevention are essential. Periodic recalibration is recommended based on usage. Proper storage prevents damage and accuracy loss.

Q. What accuracy levels can be achieved with Master Gears?

- Master Gears are produced to very high accuracy classes as per international standards.

- Tight tolerances ensure reliable flank, profile, and rolling checks.

- High accuracy minimizes measurement uncertainty. This is critical for precision gear manufacturing.

Q. Can Master Gears be re-calibrated after long-term use?

- Yes, Master Gears can be re-calibrated to verify continued accuracy.

- Periodic calibration ensures measurement

- Re-calibration intervals depend on usage frequency.

- This extends the useful life of the Master Gear.

Our Other Products

HSS Hob Cutters

Carbide Hob Cutters

Broaches

Shaper Cutter

Gear Shaving Cutters

Milling Cutters

Master Gears