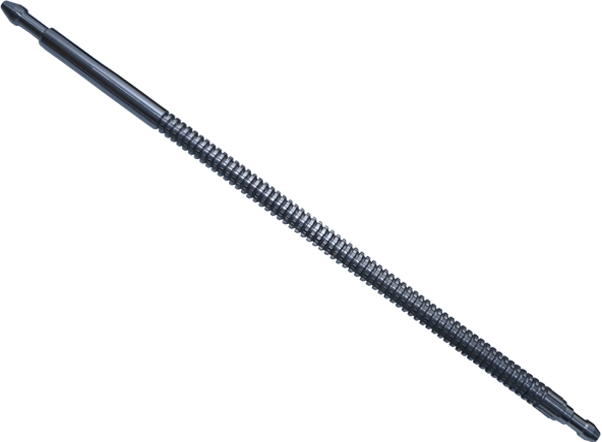

Involute Spline Broaches

STC manufactures Involute Spline Broaches; besides manufacturing Spline Broaches, we also offer repair and sharpening services for all types of broaches. Our Spline Broaches are made using high-quality imported raw materials acquired from leading vendors in the industry.

Our fully experienced and well-qualified team produces these Spline Broaches in various sizes, dimensions, and configurations per customer’s requirements.

- Involute Spline

- Straight Sided

- Serration

- Interspace

Technical Specification

| INVOLUTE SPLINE BROACHES | |

|---|---|

| Material | HSS M2, M35, M42, ASP 2030, ASP 2052, ASP 2060. |

| Standard | ANSI, DIN 5480, JIS |

| Type | Push Type and Pull Type |

| Max. Od | 280mm |

| Max. Length | Up to 2000mm |

Product FAQ’s

Q. What is an involute spline broach?

An involute spline broach is a precision cutting tool used to machine internal involute spline profiles in one continuous broaching operation, ensuring accurate tooth form and alignment. It produces uniform pressure angles and consistent spline geometry for smooth torque transmission and reliable fit between mating components.

Q. Does Super Tools manufacture custom involute spline broaches?

Yes, Involute spline broaches are also custom-manufactured by Super Tools based on detailed spline data or customer component drawings to ensure perfect tooth form accuracy. Designs are optimized for the specific material, hardness, and application to achieve consistent precision splines.

Q. Why are involute splines preferred over straight splines?

Involute splines are preferred over straight splines because they provide better load distribution across the tooth flanks, reducing stress and wear during operation. Their self-centering action allows smoother engagement and easier assembly even with minor misalignment.

Q. Are pull-type and push-type broaches available?

Yes, both pull-type and push-type broaches are available for involute spline broaching applications, depending on machine design and component requirements. Pull-type broaches are preferred for longer broaches and higher accuracy due to uniform tensile loading, while push-type broaches are used for shorter lengths and lighter cutting loads.

Q. What information is required to manufacture a broach?

To manufacture an involute spline broach, the spline standard (DIN/ISO/ANSI), module or DP, pressure angle, number of teeth, and major/minor diameters are required along with tooth form details. Material of the workpiece, hardness condition, and surface finish requirement must be specified to select broach material, tooth geometry, and cutting load. Broach type (push or pull), machine capacity, length of cut, tolerance class, and quantity complete the essential manufacturing inputs.

Q. Why choose STC involute spline broaches for precision splines?

STC involute spline broaches are chosen for their high dimensional accuracy, consistent tooth profile, and superior surface finish in precision spline cutting. They are manufactured using premium tool steels with optimized heat treatment to ensure long tool life and stable performance.

Q. What materials are used to manufacture involute spline broaches?

Involute spline broaches are typically made from high-speed steel or powder metallurgy steel. These materials provide high wear resistance and strength. Heat treatment ensures hardness and durability. Coatings can be added to improve tool life.

Q. Do involute spline broaches meet international export standards?

Export-quality involute spline broaches are manufactured following international quality standards. Dimensional inspection and material control are strictly maintained. Protective packaging prevents damage during transit. This ensures global acceptance and reliability.

Q. How are involute spline broaches installed and maintained?

Proper alignment and secure mounting are critical during installation. Regular lubrication reduces friction and wear. Periodic inspection ensures consistent performance. Re-sharpening extends tool life and accuracy.

Q. Are involute spline broaches suitable for high-volume production?

Yes, involute spline broaches are ideal for high-volume and mass production. They ensure consistent quality across large batches. Short cycle times improve productivity. This makes them cost-effective for OEM manufacturing.

Our Range of Broaches

Involute Spline Broaches

STC manufactures Involute Spline Broaches; besides manufacturing Spline Broaches...

Serration Broaches

We are a Manufacturer of Serration Broaches that is designed to be used individually or as a coupling...

Straight Spline Broaches

We are a Manufacturer of Straight Spline Broaches per world standards like DIN and JIS...

Round Broaches

We are a Manufacturer of a large selection of Round Broaches for use in various applications...

Keyway Broaches

We are a Manufacturer of Keyway Broaches, available in Inch and Metric sizes...

Square Broaches

We are a Manufacturer of Square Broaches, also known as “square hole broaches...

Helical Broaches

STC is Manufacturer of Helical Broaches to get the maximum helix angle accuracy ...