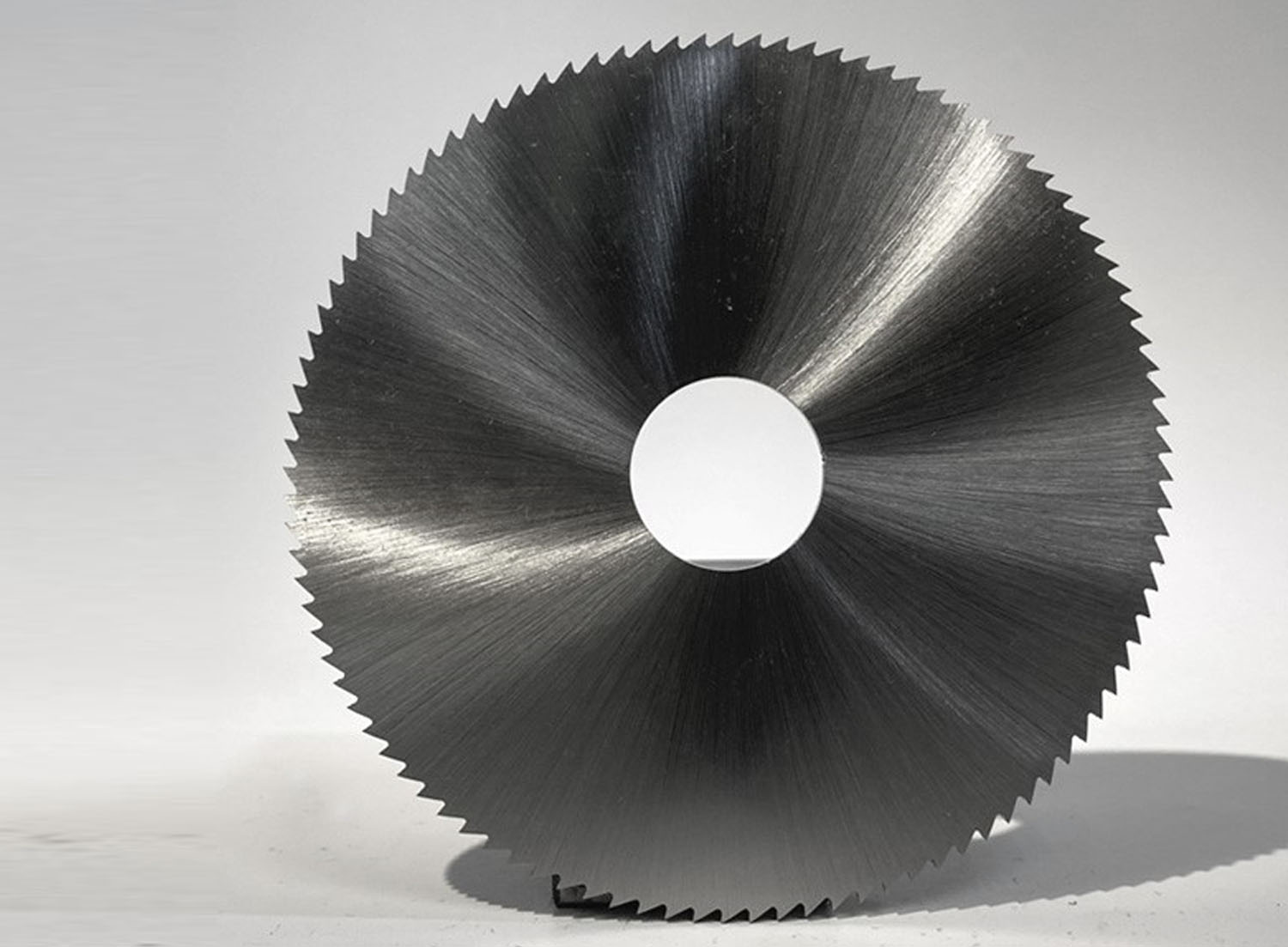

HSS Slitting Saw Cutter

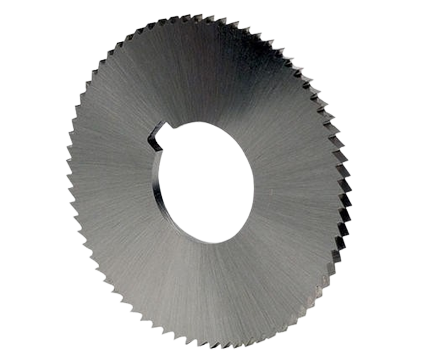

Technical Specification

| HSS SLITTING SAW CUTTER | |

|---|---|

| Thickness | 0.5 to 6mm |

| Minimum Diameter | 30 mm |

| Maximum Diameter | 250 mm |

| Coating | TiN, TiAlN, TiCN, or as required |

| Application | ferrous and non-ferrous metal industry. |

| Usage | Used for slitting and trimming mild steel, stainless steel, aluminum, |

| We also manufacture as per Customer's requirement. | |

Product FAQ’s

Q. What industries commonly use HSS slitting saw cutters?

HSS slitting saw cutters are widely used in automotive, aerospace, and general engineering industries. They are essential in tool rooms, fabrication units, and OEM manufacturing. Applications include metalworking and component separation. Both small workshops and large factories rely on them.

Q. What types of HSS slitting saw cutters are available?

HSS slitting saw cutters are available in plain, staggered tooth, side-and-face, and fine-tooth designs. Variants include solid HSS, HSS-Co, and coated HSS options. Different tooth forms suit various materials and cutting conditions. Selection depends on slot width, depth, and workpiece material.

Q. What materials can be machined using HSS slitting saw cutters?

HSS slitting saw cutters can machine mild steel, alloy steel, stainless steel, and cast iron. They are also suitable for aluminum, brass, and non-ferrous metals. Proper cutting parameters ensure tool life. Material hardness influences tooth design selection.

Q. What load capacity can HSS slitting saw cutters handle?

HSS slitting saw cutters handle moderate cutting loads with stable performance. Load capacity depends on cutter thickness, tooth pitch, and material grade. Correct feed and speed prevent overload. Proper setup enhances cutting efficiency and safety.

Q. Can HSS slitting saw cutters be customized as per drawing?

Yes, HSS slitting saw cutters can be custom manufactured as per customer drawings. Customization includes diameter, thickness, bore, and tooth profile. Special applications may require unique tooth spacing. Custom tools improve productivity and process reliability.

Q. Are coated HSS slitting saw cutters available?

Yes, HSS slitting saw cutters are available with coatings like TiN or TiAlN. Coatings improve wear resistance and reduce friction. They enhance tool life under higher cutting speeds. Coated cutters are ideal for demanding applications.

Q. What maintenance is required for HSS slitting saw cutters?

Regular cleaning and proper storage are essential for tool longevity. Cutters should be re-sharpened when edges wear. Avoid excessive heat during cutting operations. Scheduled maintenance reduces downtime and tooling costs.

Q. What export standards do HSS slitting saw cutters comply with?

HSS slitting saw cutters are manufactured in compliance with international quality standards. Dimensional accuracy and material traceability are ensured. Export packaging protects tools during transit. Compliance supports global supply requirements.

Q. Are HSS slitting saw cutters environmentally sustainable?

HSS slitting saw cutters support sustainability through long service life. Re-sharpening reduces waste and resource consumption. Efficient cutting lowers energy usage. Durable tooling contributes to responsible manufacturing practices.

Q. Why choose HSS slitting saw cutters for industrial machining?

HSS slitting saw cutters provide reliable performance and versatility. They balance cost, durability, and precision effectively. Easy maintenance adds long-term value. They remain a trusted solution in industrial machining.

Our Range of Milling Cutters

Form Milling Cutter

STC is a Manufacturer of Form Milling Cutters. We have a experts team in designing & manufacturing...

Rack Milling Cutter

We are a Manufacturer of Rack Milling Cutters, made in Single or multiple rows with Straight...

Involute Gear Cutter

We are a Manufacturer of Involute Gear Cutters. The bright finish coating on the cutting edges...

HSS Slitting Saw Cutter

We provide an extensive range of Slitting Cutters, which are ideal for metalworking applications...

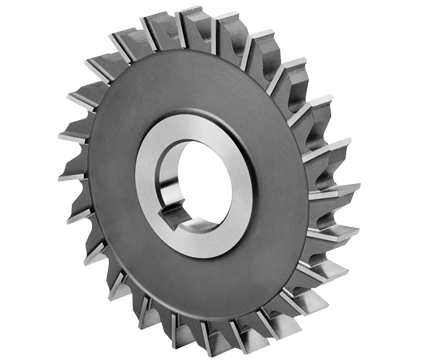

Side and Face Milling Cutter

We are a Manufacturer of Side and Face Cutter, which made in various diameters depending on usage...

Solid Carbide Milling Cutter

STC is a Manufacturer and Exporter of Solid Carbide Milling Cutters, generally used in CNC machining...