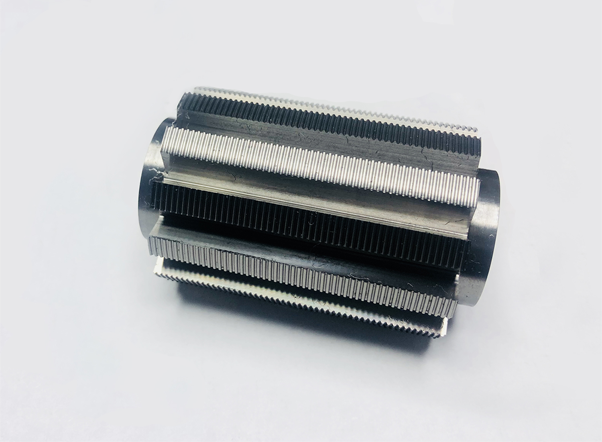

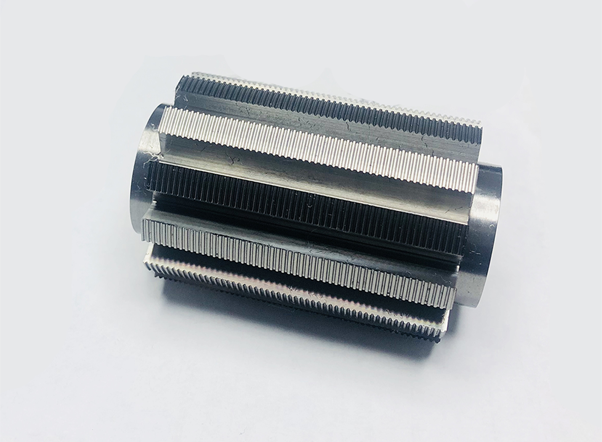

Carbide Serration Hobs

We manufacture solid Carbide Serration Hobs with fine pitch as per customer requirements. We provide these hobs with different specifications to meet the diverse requirement of customers. These are suitable for handling large bevels on small work-pieces.

Carbide Serration Hobs are also available in various angles and with all pitches. Serration Hobs are designed to cut serrations as per requirement. These Hobs deliver high wear resistance and excellent cutting stability. The carbide grade ensures long tool life and reduced tool change frequency. These hobs provide accurate serration profiles with consistent pitch control. Suitable for precision machining and high-speed production environments. Superior surface finish is achieved with controlled cutting action. Designed for reliable performance in demanding industrial applications. Manufactured under strict quality standards to ensure repeatable results.

Note: Customization is also available.

Product FAQ’s

Q. Which materials can be machined using carbide serration hobs?

They are suitable for alloy steel, carbon steel, stainless steel, case-hardened steel, and pre-hardened materials. They are also suitable for cast iron and sintered metals used in automotive and industrial components. With proper parameters, they can cut hardened materials up to high hardness levels efficiently.

Q. What types of serrations can be cut with carbide hob cutters?

Straight serrations, involute serrations, triangular serrations, and special custom serration profiles. They are suitable for both internal and external serration profiles used in shafts, hubs, and couplings. Custom tooth forms and special serration profiles can also be manufactured as per drawing or application requirements.

Q. What machines are compatible with carbide serration hobs?

Carbide serration hobs are compatible with CNC gear hobbing machines and conventional gear hobbing machines. They can also be used on spline hobbing and serration cutting machines with proper synchronization. Rigid machines with precise speed and feed control ensure optimal performance and tool life.

Q. Are serration hobs used in EV components?

Yes, serration hobs are widely used in EV components for machining motor shafts, transmission parts, and drive assemblies. They help produce precise serrations required for torque transmission and press-fit joints. Carbide serration hobs support high accuracy and consistency needed in modern electric vehicle manufacturing.

Q. Can carbide serration hobs cut fine pitch serrations?

Yes, carbide serration hobs are well suited for cutting fine pitch serrations with high precision. Their rigid construction and sharp cutting edges ensure accurate tooth form and surface finish. This makes them ideal for small, intricate serrations in high-tolerance components.

Q. Does Super Tools Corporation export carbide Serration Hob Cutter from India?

Yes, we are an active exporter from India, supplying carbide serration hobs to the USA, Europe, and other international markets. Our products are manufactured to meet global quality standards and are trusted by OEMs and precision gear manufacturers worldwide. We ensure consistent performance, reliable delivery, and strong technical support for export customers.

Q. How does coating improve tool life in serration hobs?

Coatings on serration hobs reduce friction and cutting temperature, which minimizes wear on the cutting edges during high-load operations. They improve surface hardness and resistance to abrasion, chipping, and built-up edge formation. As a result, coated serration hobs deliver longer tool life, consistent accuracy, and higher productivity.

Q. How do solid carbide serration hob cutters improve surface finish quality?

Solid carbide serration hob cutters improve surface finish quality by maintaining exceptional edge sharpness and rigidity during cutting, which reduces vibration and chatter. Their fine micro-grain structure allows smooth, controlled material removal with minimal tool deflection. This results in cleaner tooth profiles, uniform serrations, and a superior surface finish on the machined component.

Q. Are solid carbide serration hobs suitable for small-diameter components?

Yes, solid carbide serration hobs are well suited for small-diameter components because their high stiffness and strength prevent tool deflection at reduced sizes. They maintain precise tooth geometry and stable cutting action even on fine modules and narrow faces.

Our Range of Carbide Hob Cutters

Solid Carbide

Hobs

STC Manufacture high-performance Solid Carbide Hobs, which can be used in a shell...

Carbide Shank Type Hobs

STC produces Carbide Shank Type Gear Hobs with high functional tool life. Lead angles up to 45°...

Carbide Serration Hobs

We manufacture solid Carbide Serration Hobs with fine pitch as per customer requirements...

Ratchet

Hobs

Carbide Micro Hobs

We are a Manufacturer of Carbide Micro Hobs, used to cut gears having small refined micro gear...

Carbide Special Profile Hobs

We are a Manufacturer of Carbide Special Profile Hob for various components like missing teeth...