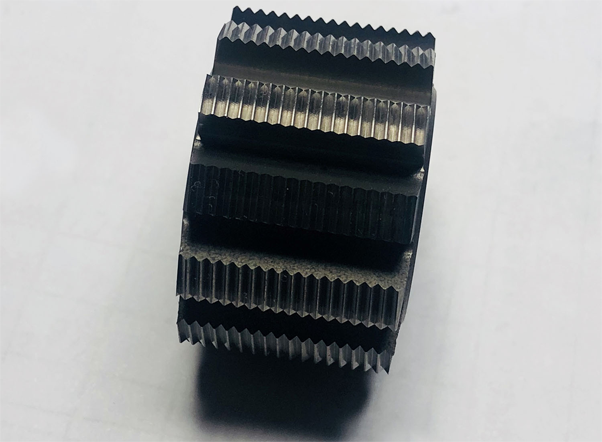

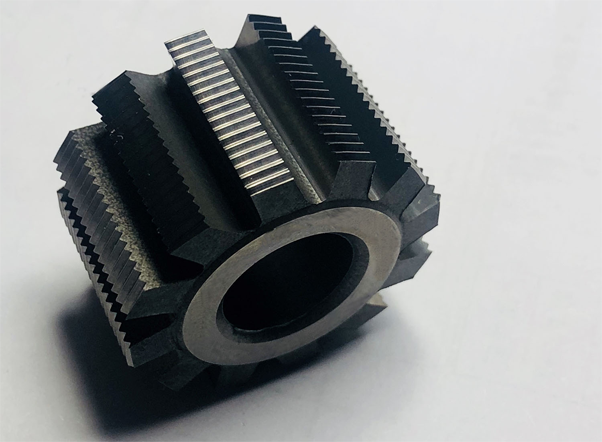

Carbide Micro Hobs

Carbide Micro Hobs are high-precision gear hobs made with or without topping. These are used in various industries and are manufactured from premium carbide materials, which ensure high durability & functionality.

Carbide Micro Hobs deliver exceptional accuracy for fine and micro gear profiles. These hobs ensure smooth cutting action and superior surface finish. Suitable for high-speed and high-precision gear manufacturing applications. Consistent pitch control supports repeatable production quality. Available in customized geometries to match specific gear designs. Designed for stable performance in demanding machining conditions. Manufactured under strict quality standards for reliable results.

Technical Specification

| CARBIDE MICRO HOBS | |

|---|---|

| Module | 0.1 to 0.8 module |

| Size and Profile | As per customer requirement |

Product FAQ’s

Q. Do carbide micro hobs provide better surface finish?

Yes, carbide micro hobs provide a superior surface finish due to their high hardness and fine-grain carbide structure. They maintain sharp cutting edges even at high speeds, reducing vibration and tool wear. This results in smoother gear tooth profiles with excellent dimensional accuracy.

Q. What standards are followed in carbide micro hob manufacturing?

Carbide micro hobs are manufactured in accordance with international standards such as ISO, DIN, and AGMA to ensure accuracy and interchangeability. These standards define tooth profile, module or DP, pressure angle, and quality grades. Compliance ensures consistent performance, precision, and global acceptance in gear manufacturing.

Q. What helix angles are available in micro hobs?

Micro hobs are available with both right-hand and left-hand helix angles, depending on the gear design. Typical helix angles range from 5° to 45° for fine and precision gears. Custom helix angles can also be manufactured as per specific drawing or application requirements.

Q. TOP Manufacturer of Carbide Micro Hob Cutter in India ?

Super Tools is a top manufacturer of carbide micro hob cutters in India, known for precision manufacturing and advanced solid carbide expertise. Its micro hobs meet strict export-quality and international gear standards. Global OEMs trust Super Tools for consistent accuracy, surface finish, and tool life.

Q. Which industries commonly use carbide micro hobs?

Carbide micro hobs are widely used in automotive, electronics, and precision engineering industries for producing fine-pitch gears. They are also essential in medical devices, robotics, and micro-motor manufacturing where high accuracy is critical. These industries benefit from superior surface finish and consistent gear quality.

Q. What is the cutting speed advantage of carbide micro hobs?

- Carbide micro hobs allow significantly higher cutting speeds compared to HSS due to their superior hardness and heat resistance.

- Higher speeds improve productivity while maintaining dimensional accuracy.

- This also results in longer tool life and stable performance in micro gear cutting.

Q. How does carbide grade selection affect micro hob performance?

Carbide grade selection directly affects micro hob performance by balancing hardness, toughness, and wear resistance for the specific work material. Fine-grain carbide grades improve edge sharpness and dimensional accuracy, while tougher grades reduce chipping in high-speed or interrupted cutting.

Q. How does coating improve tool life in carbide micro hobs?

Coating improves tool life in carbide micro hobs by reducing friction and cutting temperatures at the tool–workpiece interface. It increases wear resistance against abrasion and adhesion, protecting the sharp micro cutting edges from premature failure. Advanced coatings also minimize built-up edge formation, ensuring consistent performance and longer service life.

Our Range of Carbide Hob Cutters

Solid Carbide

Hobs

STC Manufacture high-performance Solid Carbide Hobs, which can be used in a shell...

Carbide Shank Type Hobs

STC produces Carbide Shank Type Gear Hobs with high functional tool life. Lead angles up to 45°...

Carbide Serration Hobs

We manufacture solid Carbide Serration Hobs with fine pitch as per customer requirements...

Ratchet

Hobs

Carbide Micro Hobs

We are a Manufacturer of Carbide Micro Hobs, used to cut gears having small refined micro gear...

Carbide Special Profile Hobs

We are a Manufacturer of Carbide Special Profile Hob for various components like missing teeth...